ASTM A335 Steel Pipe

| Ngalan sa Produkto | Alloy Steel Pipe |

| Materyal nga | Alloy nga Steel |

| Ang gitas-on sa tubo | Single Random Length ug doble Random Length.SRL:3M-5.8M DRL:10-11.8M o Ingon sa gipangayo sa mga kliyente ang gitas-on |

| Gidak-on | Gidak-on 1/4”ngadto sa 24”Sa gawas Diametro 13.7 mm ngadto sa 609.6 mm |

| Gibag-on sa dingding | SCH10, SCH20, SCH30, STD, SCH40, SCH60, SCH80, SCH100 SCH120, SCH160, XS, XXS |

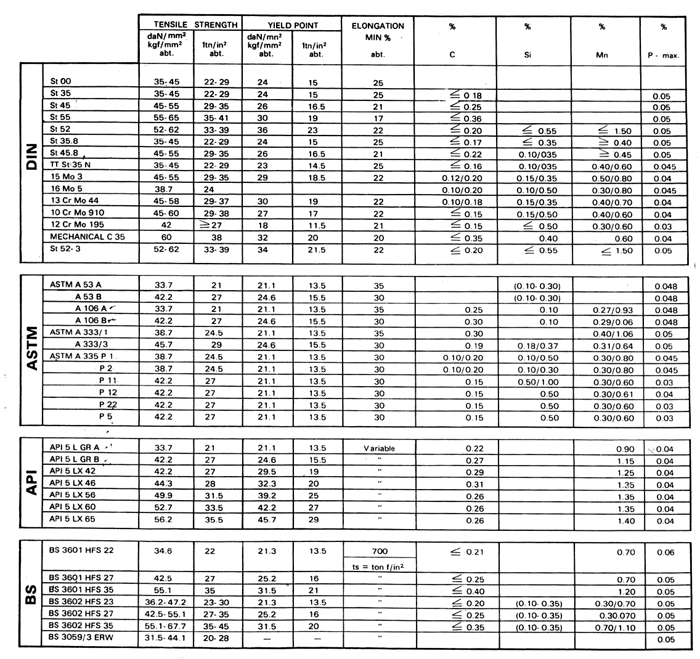

| Estandard | ASTM A 335 Grade P1, P2, P5, P9, P9A, P11, P22.ASTM A213 T1B, T1, T2, T5, T9, T9A, T11, T12, T22.A199 T5, T9, T11, T22.BS 3604 Grade 621, 622, 625, 629-470, 629-590, 660, 762.DIN 17175 15 Mo 3, 13 Cr Mo 44, 10 Cr Mo 910, 14 Mo V 63. X 20 Cr MoBS V 325 , 620-460, 622-490, 629-470, 629-590, 762. JISG3458/G3462/3467 ug DIN17175-79. |

| Mga aplikasyon | 1. Fluid nga tubo 2. Power Plant 3. Structure pipe 4. Taas ug ubos nga pressure Boiler tube 5. Seamless steel tubes alang sa petrolyo cracking 6. Paagi sa tubo 7. Scaffolding pipe pharmaceutical ug ship building etc |

| Sertipiko | ISO/PED/TUV/SGS/LR/BV |

| Panguna nga Merkado | Asia, Middle East, Europe, America, Africa, Australia, ug uban pa |

Kemikal nga Komposisyon(%):

| Grado | Pagtudlo sa UNS | Komposisyon, % | |||||||

| Carbon | Manganese | posporus, | Sulfur | Silicon | Chromium | Molybdenum | Ang uban | ||

| max | max | ||||||||

| P1 | K11522 | 0.10–0.20 | 0.30–0.80 | 0.025 | 0.025 | 0.10–0.50 | — | 0.44–0.65 | — |

| P2 | K11547 | 0.10–0.20 | 0.30–0.61 | 0.025 | 0.025 | 0.10–0.30 | 0.50–0.81 | 0.44–0.65 | — |

| P5 | K41545 | 0.15 max | 0.30–0.60 | 0.025 | 0.025 | 0.50 max | 4.00–6.00 | 0.45–0.65 | — |

| P9 | S50400 | 0.15 max | 0.30–0.60 | 0.025 | 0.025 | 0.25–1.00 | 8.00–10.00 | 0.90–1.10 | — |

| P11 | K11597 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50–1.00 | 1.00–1.50 | 0.44–0.65 | — |

| P12 | K11562 | 0.05–0.15 | 0.30–0.61 | 0.025 | 0.025 | 0.50 max | 0.80–1.25 | 0.44–0.65 | — |

| P15 | K11578 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 1.15–1.65 | — | 0.44–0.65 | — |

| P21 | K31545 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50 max | 2.65–3.35 | 0.80–1.06 | — |

| P22 | K21590 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50 max | 1.90–2.60 | 0.87–1.13 | — |

| P23 | K41650 | 0.04–0.10 | 0.10–0.60 | 0.03 | 0.01 | 0.50 max | 1.90–2.60 | 0.05–0.30 | V 0.20–0.30 |

| Cb 0.02–0.08 | |||||||||

| B 0.0005–0.006 | |||||||||

| N 0.030 max | |||||||||

| Al 0.030 max | |||||||||

| W 1.45–1.75 | |||||||||

| P91 | K91560 | 0.08–0.12 | 0.30–0.60 | 0.02 | 0.01 | 0.20–0.50 | 8.00–9.50 | 0.85–1.05 | V 0.18–0.25 |

| N 0.030–0.070 | |||||||||

| Ni 0.40 max | |||||||||

| Al 0.04 max | |||||||||

| Cb 0.06–0.10 | |||||||||

| P92 | K92460 | 0.07–0.13 | 0.30–0.60 | 0.02 | 0.01 | 0.50 max | 8.50–9.50 | 0.30–0.60 | V 0.15–0.25 |

| N 0.03–0.07 | |||||||||

| Ni 0.40 max | |||||||||

| Al 0.04 max | |||||||||

| Cb 0.04–0.09 | |||||||||

| W 1.5–2.00 | |||||||||

| B 0.001–0.006 | |||||||||

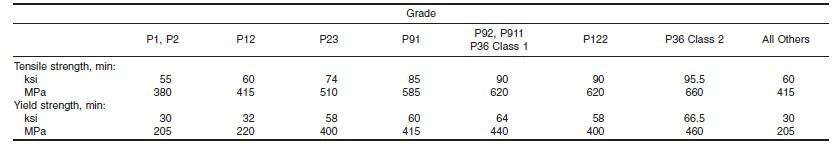

Mga Kinaiya sa Mekanikal:

Itom nga taklap, lana / barnis, FBE, 2PE, 3PE, galvanized etc Detalye sa Packaging: Pagputos sa mga bundle o alang sa kinahanglanon sa kliyente