Titanium Oruka

Awọn oruka titanium ti o tobi ni a ti ṣelọpọ nipasẹ ẹrọ ti npa titobi nla, awọn oruka titanium kekere le ṣee ṣe nipasẹ ẹrọ fifọ.Gẹgẹbi ile-iṣẹ ti o ni diẹ sii ju ọdun 20 ti iriri iṣelọpọ, a ni lẹsẹsẹ ti ilana ayederu lile ati afọwọṣe iṣiṣẹ, pẹlu awọn igbesẹ alapapo, akoko alapapo ati akoko itọju ooru.35MN ati 16MN ẹrọ ayederu iyara ṣe iṣeduro ọpọlọpọ ayederu ni iwọn otutu ti o dara, o si yi eto ti ara inu ti awọn oruka titanium pada.Gidigidi dara si awọn didara ti awọn ọja wa.

Ni afikun si oruka titanium, a tun pese iṣelọpọ ti disiki titanium, bulọọki titanium ati bẹbẹ lọ.

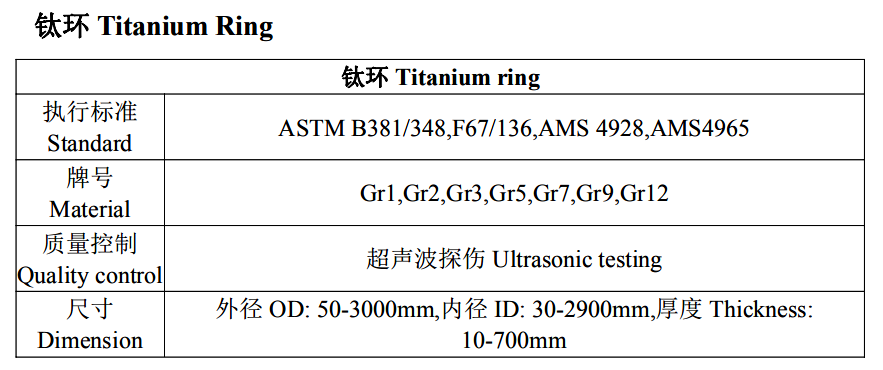

| ọja orukọ | Titanium Oruka |

| Iwọn | OD (max3000mm)×ID (max2900mm)×ipari (o pọju ipari 1000mm) |

| Ipele | TA1/TA2/TA5/TA6/TA9/TA10/TA15/TA19/TC1/TC2/TC4/TC11/ GR1/GR2/GR5/GR7/GR9/GR12/GR23 |

| Awọn ajohunše | ASTM B381/348,F67/136,AMS4928,AMS4965,AMS,MIL,DIN,BS,JIS,GB/T,ISOati be be lo |

| iwuwo | 4.51g / cm3 Ga išẹ ile ise forging, gr12 Titanium eke sẹsẹ oruka |

| Imọ ọna ẹrọ | Forging, sẹsẹ, lilọ ga išẹ ile ise forging GR12 titanium forging sẹsẹ oruka |

| Iru | Ilana ti yiyi oruka ti ko ni abawọn pẹlu gige iho kan ninu ohun elo ayederu ati yiyi sinu oruka tinrin. Ti a ṣe afiwe si ibọn awo tabi alurinmorin apọju, oruka ayederu ti yiyi n pese ilọsiwaju concentric pẹlu iwọn dada didan Iwọn iṣẹ giga ti ile-iṣẹ eke GR12 titanium eke oruka yiyi |

| Ohun elo | 1. Electrolating;2.Imọ-ẹrọ Kemikali ati Kemikali;3.Iṣoogun ti o ga julọ ile-iṣẹ eke GR12 titanium forging sẹsẹ oruka |

ASTM B381/348,F67/136,AMS4928,AMS4965

Kemikali tiwqn

| Ipele | Akopọ kẹmika, iwuwo ogorun (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Awọn eroja miiran O pọju.kọọkan | Awọn eroja miiran O pọju.lapapọ | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5-6.75 | 3.5-4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5-3.5 | 2.0-3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 ~ 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5-6.5 | 3.5-4.5 | - | - | - | - | 0.1 | 0.1 |

Awọn ohun-ini ti ara

| Ipele | Awọn ohun-ini ti ara | |||||

| Agbara fifẹ Min | Agbara ikore Min (0.2%, aiṣedeede) | Ilọsiwaju ni 4D Min (%) | Idinku ti Area Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |