Erogba Irin Seamless Pipe

Ailokun Irin Pipe ti wa ni ṣe lati kan ri to yika irin'billet'eyi ti o jẹ kikan ati titari tabi fa lori fọọmu kan titi ti irin yoo fi ṣe apẹrẹ sinu tube ṣofo.Paipu ti ko ni ailopin lẹhinna pari si iwọn ati awọn alaye sisanra ogiri ni awọn iwọn lati 1/8 inch si 32 inch OD.Erogba Irin Seamless Pipes / Awọn tubes Erogba, irin jẹ alloy ti o ni irin ati erogba.Awọn ogorun ti erogba ninu irin ni ipa lori líle, agbara ti elasticity ati ductility ti erogba, irin.Paipu erogba ti ko ni ailopin tabi ingot irin to lagbara jẹ ti tube capillary nipasẹ iho, lẹhinna nipasẹ yiyi gbigbona, yiyi tutu tabi ipe tutu ni a ṣe.Aipin erogba irin pipe ni China ká irin ile ise ni o ni ohun pataki ipo.Ailokun erogba, irin pipe ohun elo ni a yika tube, paipu Ige ẹrọ oyun lati lọ nipasẹ gige nipa 1 m ti ipari òfo, ati ki o rán nipasẹ conveyor igbanu ileru alapapo.Billet ti wa ni je sinu alapapo ileru, awọn iwọn otutu jẹ nipa 1200 iwọn Celsius.Epo jẹ hydrogen tabi acetylene.Iṣakoso iwọn otutu ileru jẹ ọrọ pataki.Yika tube jade lati Punch nipasẹ awọn ẹrọ nipasẹ air titẹ.Ni gbogbogbo diẹ sii wọpọ punch ti wa ni tapered eerun perforation ẹrọ, awọn Punch ga gbóògì ṣiṣe, ọja didara, ti o tobi iwọn ila opin iho imugboroosi, le wọ a orisirisi ti irin.Perforation, yika tube ti wa lori mẹta-eerun agbelebu sẹsẹ, sẹsẹ tabi extrusion.Pa tube lẹhin ti iwọn.Titobi nipasẹ awọn iho konu rotari iyara to ga sinu billet lati ṣe tube kan.Iwọn ila opin paipu nipasẹ ọlọ lati pinnu ipari ti iwọn ila opin liluho.Lẹhin paipu nipasẹ titobi sinu ile-iṣọ itutu agbaiye, itutu agbaiye nipasẹ sokiri omi, irin lẹhin itutu agbaiye, yẹ ki o wa ni taara.Lẹhin igbanu irin ti a firanṣẹ nipasẹ titọ ẹrọ idanwo irin (tabi idanwo titẹ) fun idanwo inu.Ti o ba ti paipu ti abẹnu dojuijako, nyoju ati awọn miiran isoro yoo ṣee wa-ri.Lẹhin paipu ṣugbọn tun nipasẹ yiyan iṣakoso didara ti o muna.Didara irin, lilo awọn nọmba awọ sokiri, awọn pato, nọmba pipọ iṣelọpọ.Nipa a Kireni sinu ile ise.

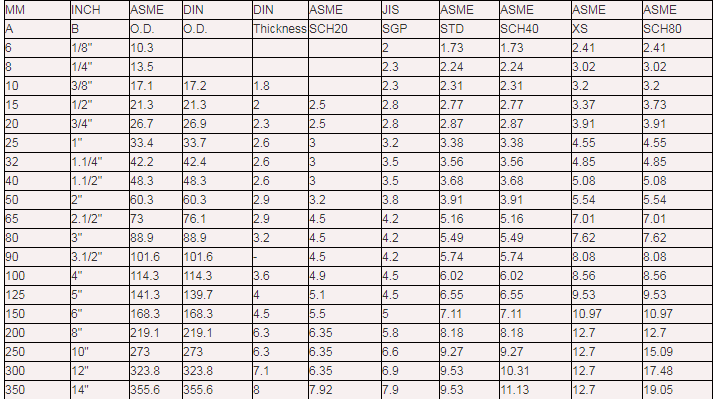

Odi sisanra ti laisiyonu paipu

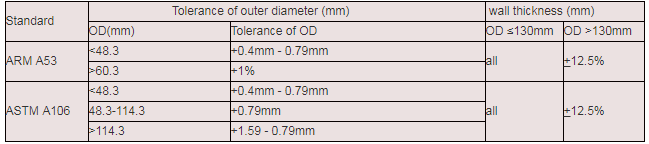

Ifarada ti Ode Iwọn ati sisanra Odi

| Standard | Apejuwe |

| ASTM A179/A179M | Ailokun tutu fa alloy irin kekere ti n paarọ ooru ati awọn tubes condenser. |

| API 5L | Paipu ila. |

| ASTM A53M | Dudu & Zinc Ti a bo Welded ati Alailẹgbẹ Irin Pipe. |

| ASTM A106M | Ailokun erogba irin pipe fun iṣẹ iwọn otutu giga. |

| ASTM A105M | Erogba, irin forgings fun fifi ọpa. |

| ASTM A234M | Awọn ohun elo fifin ti irin erogba ti a ṣe ati irin alloy fun iwọntunwọnsi ati iṣẹ iwọn otutu giga. |

| ASTM 3799 | Awọn ohun elo paipu irin, dabaru ati weldability iho fun ile-iṣẹ epo. |

| AS 1163 | Igbekale irin ṣofo ruju |

| AS 1074 | Awọn tubes irin ati awọn tubulars fun iṣẹ lasan |

| BS13872 | Ti dabaru ati socketed irin tube ati tubulars |

| Standard | Iru paipu | Kilasi | Ipele |

| API SPEC 5L ISO 3183 | SMLS | PLS1 | L245B, L290 X42, L320 X46 , L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| PLS2 | L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q, L485Q X70Q

| ||

| PLS2 Ekan Ayika | L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS

| ||

| WELD | PLS1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| PLS2 | L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, | ||

| Standard | Ipele |

| ASTM A 53 M | A, B |

| ASTM A 106M | A, B, C |

| JIS G 3454 | STPG 370, STPG 410 |

| JIS G 3455 | STPG370, STPG410, STPG480 |

| JIS G 3456 | STPG370, STPG410, STPG480 |

Ipele: Iṣọkan Kemikali (%):

| Standard | Ipele | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| ASTMA 53M | A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | - | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| ASTM A 106M | A | ≤0.25 | ≥0.10 | 0.27-0.93 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| JIS G 3454 | STPG 370 | ≤0.25 | ≤0.35 | 0.30-0.90 | ≤0.040 | ≤0.040 | - | - | - | - | - |

| STPG 410 | ≤0.30 | ≤0.35 | 0.30-1.00 | ≤0.040 | ≤0.040 | - | - | - | - | - | |

| JIS G 3455 | STS 370 | ≤0.25 | 0.10-0.35 | 0.30-1.10 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STS 410 | ≤0.30 | 0.10-0.35 | 0.30-1.40 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STS 480 | ≤0.33 | 0.10-0.35 | 0.30-1.50 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| JIS G 3456 | STPT 370 | ≤0.25 | 0.10-0.35 | 0.30-0.90 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STPT 410 | ≤0.30 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STPT 480 | ≤0.33 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - |

Itọju dada ti paipu irin: Lati le mu igbesi aye iṣẹ ti opo gigun ti epo, itọju dada ni a maa n ṣe lati dẹrọ apapo iduroṣinṣin ti paipu irin ati ibora anticorrosive.Awọn ọna ṣiṣe ti o wọpọ jẹ: mimọ, derusting ọpa, pickling, shot iredanu derusting mẹrin isori.1 CleanGrease, eruku, lubricant, Organic ọrọ ti o ni ibamu lori oju ti paipu irin, nigbagbogbo lilo epo, emulsion lati nu oju-aye.Sibẹsibẹ, ipata, awọ-ara oxide ati slag alurinmorin lori oju ti paipu irin ko le yọ kuro, nitorinaa miiran itọju awọn ọna ti wa ni ti nilo.Tool ipata removalSteel pipe dada oxide, ipata, alurinmorin slag, le lo irin waya fẹlẹ lati nu ati pólándì awọn dada itọju.Tool derusting le ti wa ni pin si Afowoyi ati agbara, Afowoyi ọpa derusting le de ọdọ Sa 2 ipele, agbara. derusting ọpa le de ọdọ ipele Sa3. Ti o ba jẹ pe oju ti paipu irin ti wa ni asopọ pẹlu awọ-ara oxide ti o lagbara julọ, o le jẹ pe ko ṣee ṣe lati yọ ipata kuro pẹlu iranlọwọ ti awọn irinṣẹ, nitorina a nilo lati wa awọn ọna miiran.3 pickling wọpọ pickling ọna pẹlu kemistri ati electrolysis.Sugbon nikan kemikali pickling ti wa ni lo fun opo gigun ti epo Idaabobo.Chemical pickling le se aseyori kan awọn ìyí ti cleanliness ati roughness lori dada ti irin paipu, eyi ti o jẹ rọrun fun tetele oran ila.Usually bi a shot (iyanrin) lẹhin reprocessing.4 shot iredanu fun ipata yiyọ Nipa agbara giga motor wakọ awọn ga-iyara yiyi abe, irin grit, irin shot, apa, ohun alumọni ati awọn miiran abrasive waya labẹ awọn iṣẹ ti centrifugal agbara lori irin pipe dada sokiri ati ibi-ejection, daradara yọ ipata, oxides ati idọti ni ọwọ kan, ni apa keji, paipu irin labẹ iṣe ti ipa ipa-ipa abrasive ati agbara ija, lati ṣaṣeyọri aibikita aṣọ ti a beere.Among awọn ọna itọju mẹrin, fifun ibọn ati derusting jẹ ọna itọju pipe fun pipe derusting.Ni gbogbogbo, fifẹ fifẹ ati derusting ni a lo ni pataki fun itọju oju inu ti paipu irin, ati fifun ibọn ati derusting ni a lo ni pataki fun itọju dada ita ti paipu irin.

Sokiri kun

Sokiri kun

Mabomire apoti