Kanal

A36 Steel Channel issiq haddelenmiş, yumshoq po'latdan yasalgan konstruktiv C shakli bo'lib, ichki radius burchaklari bilan barcha strukturaviy ilovalar, umumiy ishlab chiqarish, ishlab chiqarish va ta'mirlash uchun idealdir.Chelik kanali sanoatga texnik xizmat ko'rsatish, qishloq xo'jaligi asbob-uskunalari, transport uskunalari, yuk mashinalari yotoqlari, tirkamalar va boshqalarda keng qo'llaniladi. Uning C shaklidagi yoki U shaklidagi konfiguratsiyasi loyihangiz yuki vertikal yoki gorizontal bo'lganda po'lat burchakdan qo'shimcha mustahkamlik va qattiqlik uchun idealdir.Ushbu po'lat shaklini payvandlash, kesish, shakllantirish va tegishli asbob-uskunalar va bilimlar bilan ishlov berish oson.Metall ombori yuzlab o'lchamdagi po'lat kanallarni ulgurji narxlarda oldindan kesilgan va tegirmon uzunligida jo'natishga tayyor yoki siz o'zingizga kerakli narsani kichik yoki katta miqdorda buyurtma qilishingiz mumkin.A-36 Steel Channel uzoq muddatli korroziyadan himoya qilish uchun galvanizli qoplamali qoplamada ham mavjud.

| Issiq haddelenmiş kanalli po'lat | |||

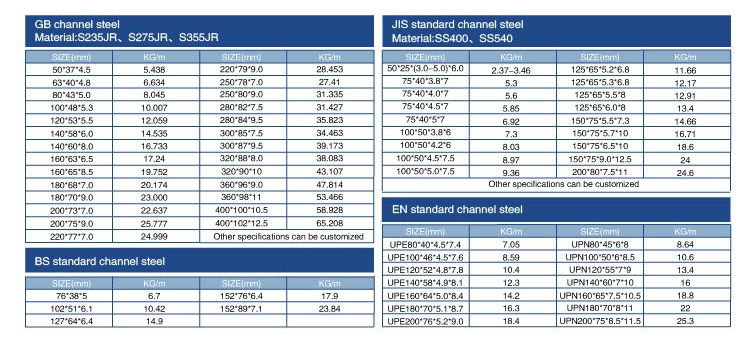

| Ijroiya standarti | GB/T 707-1988 | JIS G 3192-2006 | DIN 1026-1: 2000 |

| Chelik darajasi | Q235B | SS400 | S235JR |

| Umumiy o'lcham | 5# 50*37*4.5mm - 40B 400*102*12,5 mm | 5# 50*25*3mm – 200*80*7,5mm | UPN140 - UPN200 |

| Uzunlik | 6 m, 10 m, 12 m yoki mijozning so'rovini konteynerga yuklash uchun 5,5 m, 5,8 m sifatida bajarishi mumkin. | ||

| Afzalliklar | 1. yuqori sifat2.yuqori o'lchov aniqligi3.xarajatlarni tejash | ||

| Ilova | Bino tuzilishi, parda devori muhandisligi, mexanik uskunalar va transport vositalari ishlab chiqarish va boshqalar | ||

| Qadoqlash | Professional eksport qadoqlash yoki mijozlar talablariga muvofiq. | ||

| Sovuq bükme kanali po'latdir | |||

| Umumiy o'lcham | kengligi: 10-400 mm, qalinligi: 1-16 mm | ||

| Uzunlik | 6m, 9m, 12m yoki mijozning so'rovini konteynerga yuklash uchun 5,5 m, 5,8 m sifatida bajarishi mumkin. | ||

| Afzalliklar | Issiq haddelenmiş kanal po'latini ishlab chiqarish mumkin bo'lmagan texnik xususiyatlarni to'ldiring.Spetsifikatsiya va qalinligi moslashtirilgan o'lchamga muvofiq qayta ishlanishi mumkin | ||

ASTM A53/ASTM A573/ASTM A283 Gr.D/BS1387-1985/GB/T3091-2001,

GB/T13793-92, ISO630/E235B/JIS G3131/JIS G3106

| Baho | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 ,75 | 5. 5-7.5 | ≤0,06 | ≤ 0,03 | 3,5 -5,5 | 16 ,0 -18,0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7,5-10,0 | ≤0,06 | ≤ 0,03 | 4,0-6,0 | 17,0-19,0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2,0 | ≤0,045 | ≤ 0,03 | 6,0-8,0 | 16,0-18,0 | - |

| 302 | ≤0 .15 | ≤1,0 | ≤2,0 | ≤0,035 | ≤ 0,03 | 8,0-10,0 | 17,0-19,0 | - |

| 304 | ≤0 .0.08 | ≤1,0 | ≤2,0 | ≤0,045 | ≤ 0,03 | 8,0-10,5 | 18,0-20,0 | - |

| 304 l | ≤0,03 | ≤1,0 | ≤2,0 | ≤0,035 | ≤ 0,03 | 9,0-13,0 | 18,0-20,0 | - |

| 309S | ≤0,08 | ≤1,0 | ≤2,0 | ≤0,045 | ≤ 0,03 | 12,0-15,0 | 22,0-24,0 | - |

| 310S | ≤0,08 | ≤1,5 | ≤2,0 | ≤0,035 | ≤ 0,03 | 19,0-22,0 | 24,0-26,0 | |

| 316 | ≤0,08 | ≤1,0 | ≤2,0 | ≤0,045 | ≤ 0,03 | 10,0-14,0 | 16,0-18,0 | 2,0-3,0 |

| 316 l | ≤0 ,03 | ≤1,0 | ≤2,0 | ≤0,045 | ≤ 0,03 | 12,0 - 15,0 | 16 .0 -1 8.0 | 2,0 -3,0 |

| 321 | ≤ 0,08 | ≤1,0 | ≤2,0 | ≤0,035 | ≤ 0,03 | 9,0 – 13,0 | 17,0 -1 9,0 | - |

| 630 | ≤ 0 .07 | ≤1,0 | ≤1,0 | ≤0,035 | ≤ 0,03 | 3,0-5,0 | 15,5-17,5 | - |

| 631 | ≤0,09 | ≤1,0 | ≤1,0 | ≤0,030 | ≤0,035 | 6.50-7.75 | 16,0-18,0 | - |

| 904 l | ≤ 2 .0 | ≤0,045 | ≤1,0 | ≤0,035 | - | 23,0·28,0 | 19,0-23,0 | 4,0-5,0 |

| 2205 | ≤0,03 | ≤1,0 | ≤2,0 | ≤0,030 | ≤0,02 | 4,5-6,5 | 22,0-23,0 | 3,0-3,5 |

| 2507 | ≤0,03 | ≤0,8 | ≤1.2 | ≤0,035 | ≤0,02 | 6,0-8,0 | 24,0-26,0 | 3,0-5,0 |

| 2520 | ≤0,08 | ≤1,5 | ≤2,0 | ≤0,045 | ≤ 0,03 | 0,19 -0.22 | 0. 24 -0 .26 | - |

| 410 | ≤0,15 | ≤1,0 | ≤1,0 | ≤0,035 | ≤ 0,03 | - | 11,5-13,5 | - |

| 430 | ≤0,1 2 | ≤0,75 | ≤1,0 | ≤ 0,040 | ≤ 0,03 | ≤0,60 | 16,0 -18,0 | - |

| A36 STEEL KANAL TOLERANSLARI(+/-) | ||||||

| Kanal hajmi | Kanal chuqurligi | Flanj kengligi | 10 futda tekislik | Uzunliklari +/- | Kvadratdan tashqarida | |

| Maxsus kesish | Standart | |||||

| 1/2 dan 1-1/2 gacha | 1/32 | 1/32 | 1/4 | 1/16 | 1/4 | 1/32 |

| 1-1/2 dan 3 gacha | 1/16 | 1/16 | 1/4 | 1/16 | 1/4 | 1/32 |

| 3 dan 7 gacha | 3/32 | 1/8 | 1/4 | 1/8 | 1/4 | 1/32 |

| 7 dan 14 gacha | 1/8 | 1/8 | 1/4 | 1/8 | 1/4 | 1/32 |

| 14 dan yuqori | 3/16 | 1/8 | 1/4 | 1/8 | 1/2 | 1/32 |

| Bu erda keltirilgan tolerantlik qiymatlari faqat ma'lumot olish uchun mo'ljallangan va kafolatlanmagan. | ||||||