Titan Pipe / Tube

Titan nahtlos Rouer gëtt duerch den Ofbau vun Titan Ingot veraarbecht, extrudéiert op Titan Tube Billet.Dann produzéiere Titan Réier zu passenden Gréisst mat Serie vu Prozesser wéi Multiple Walzen, annealing, Pickling, a Schleifen Technologie.

Titan geschweißte Röhre ass andeems Dir eng gëeegent Dicke vun der héichqualitativer kalgewalzter Titanplack auswielt, nom Prozess vum Offlachen, Ausschneiden a Wäschen, duerno Titanplack a Réier opgerullt, Schweess duerch déi ganz automatesch Schweißausrüstung.Eis fortgeschratt Schweessausrüstung garantéiert d'Qualitéit vum Schweess.Schlussendlech hëllefe fir déi exzellent Qualitéit Titan Röhre ze produzéieren.

Titan nahtlos Tube

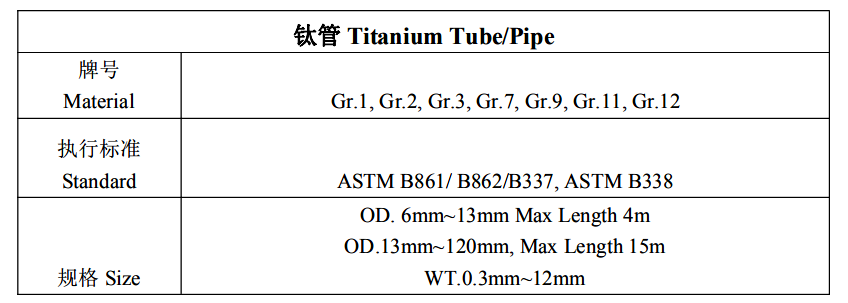

Grad: Gr1, Gr2, Gr7, Gr9, Gr11, Gr12, Gr16 etc

Baussenduerchmiesser: 3 ~ 110 mm

Wanddicke: 0,1 ~ 5,5 mm

Längt: ≤19000mm

Titan Schweess Röhre

Grad: Gr1, Gr2, Gr7, Gr9, Gr11, Gr12, Gr16 etc

Baussenduerchmiesser: 10 ~ 1000 mm

Wanddicke: 0,5 ~ 5,5 mm

Längt: ≤19000mm

Gr5, Gr23 Titanlegierung nahtlos Tube

Baussenduerchmiesser: 20 ~ 110 mm

Wanddicke: 1-50 mm

Längt: ≤3000mm

Fabrikatioun Prozess: Bueraarbechten, Hot Rolling

| SEAMLESS TITANIUM PIPE | ||||||||||

|

| S10 | S40 | S80 | |||||||

| Pipe Gréisst | OD | Mauer | Bannen Dia. | lbs/ft | Mauer | Bannen Dia. | lbs/ft | Mauer | Bannen Dia. | lbs/ft |

| 1/8 | .405 | .049 | .307 | .1072 | .068 | .269 | .1408 | .095 | .215 | .1810 |

| 1/4 | .540 | .065 | .410 | .1897 | .088 | .364 | .2442 | .119 | .302 | .3079 |

| 3/8 | .675 | .065 | .545 | .2437 | .091 | .493 | .3266 | .126 | .423 | .4251 |

| 1/2 | .840 | .083 | .674 | .3861 | .109 | .622 | .4896 | .147 | .546 | .6260 |

| 3/4 | 1.050 | .083 | .884 | .4932 | .113 | .824 | .6506 | .154 | .742 | .8479 |

| 1 | 1.315 | .109 | 1.097 | .8078 | .133 | 1.049 | .9660 | .179 | .957 | 1.2495 |

| 1-1/4 | 1.660 | .109 | 1.442 | 1.0389 | .140 | 1.380 | 1.3077 | .191 | 1.278 | 1.7242 |

| 1-1/2 | 1.900 | .109 | 1.681 | 1.1996 | .145 | 1.610 | 1.5637 | .200 | 1.500 | 2,0893 |

| 2 | 2.375 | .109 | 2.157 | 1.5178 | .154 | 2.067 | 2.1018 | .218 | 1.939 | 2,8895 |

| 2-1/2 | 2.875 | .120 | 2.635 | 2.0315 | .203 | 2.469 | 3,3331 | .276 | 2.323 | 4,4080 |

| 3 | 3.500 | .120 | 3.260 | 2.4924 | .216 | 3.068 | 4,3589 | .300 | 2.900 | 5,8992 |

| 3-1/2 | 4.000 | .120 | 3.760 | 2,8611 | .226 | 3.548 | 5.2412 | .318 | 3.364 | 7.1950 |

| 4 | 4.500 | .120 | 4.260 | 3,2298 | .237 | 4,026 | 6.2085 | .337 | 3.826 | 8,6210 |

| 5 | 5.563 | .134 | 5.295 | 4,4704 | .258 | 5.047 | 8,4106 | .375 | 4,813 | 11.9550 |

| 6 | 6.625 | .134 | 6.357 | 5.3449 | .280 | 6.065 | 10,917 | .432 | 5.761 | 16.440 |

| WELDED TITANIUM PIPE | |||||||

|

| S10 | S40 | |||||

| Pipe Gréisst | OD | Mauer | Bannen Dia. | lbs/ft | Mauer | Bannen Dia. | lbs/ft |

| 3/4 | .1.050 | .083 | .884 | .4932 | .113 | .824 | .6506 |

| 1 | 1.315 | .109 | 1.097 | .8078 | .133 | 1.049 | .9660 |

| 1-1/4 | 1.660 | .109 | 1.442 | 1.0389 | .140 | 1.380 | 1.3077 |

| 1-1/2 | 1.900 | .109 | 1.681 | 1.1996 | .145 | 1.610 | 1.5637 |

| 2 | 2.375 | .109 | 2.157 | 1.5178 | .154 | 2.067 | 2.1018 |

| 2-1/2 | 2.875 | .120 | 2.635 | 2.0315 | .203 | 2.469 | 3,3331 |

| 3 | 3.500 | .120 | 3.260 | 2.4924 | .216 | 3.068 | 4,3589 |

| 3-1/2 | 4.000 | .120 | 3.760 | 2,8611 | .226 | 3.548 | 5.2412 |

| 4 | 4.500 | .120 | 4.260 | 3,2298 | .237 | 4,026 | 6.2085 |

| 5 | 5.563 | .134 | 5.295 | 4,4704 | .258 | 5.047 | 8,4106 |

| 6 | 6.625 | .134 | 6.357 | 5.3449 | .280 | 6.065 | 10,917 |

| 8 | 8.625 | .148 | 8.329 | 7.7095 | .322 | 7.981 | 16.429 |

| 10 | 10.750 | .165 | 10,420 | 10.732 | .365 | 10.020 | 23.293 |

| 12 | 12.750 | .180 | 12.390 | 13.904 | .375 | 12.000 | 28.517 |

| 14 | 14.000 | .188 | 13.624 | 15.956 | .375 | 13.250 | 31.397 |

| 16 | 16.000 | .188 | 15.624 | 18.267 | .375 | 15.250 | 36.006 |

| 18 | 18.000 | .188 | 17.624 | 20.577 | .375 | 17.250 | 40,615 |

| 20 | 20.000 | .218 | 19.564 | 26.500 | .375 | 19.250 | 45.223 |

| 24 | 24.000 | .250 | 23.500 | 36.486 | .375 | 23.250 | 54.441 |

ASTM B338 - 10e1 Standard Spezifizéierung fir nahtlos a geschweißt Titan an Titanlegierung Tubes fir Kondensatoren an Wärmetauscher

ASTM B862 - 09 Standard Spezifizéierung fir Titan an Titan Alloy geschweißte Pipe

ASTM B861 - 10 Standard Spezifikatioun fir Titan an Titanlegierung Nahtlos Pipe, ASTM B337

| Titan Tube / Pipe | Produit Numm | Grad | Spezifizéierung (mm) | Standard |

| Nahtlos Tube | Gr.1 Gr.2 Gr.7 Gr.9 Gr.12

| OD(3-114)×THK(0,5-10) ×≤ Längt 12000 | ASTM B337 ASTM B338 ASTM B 861 | |

| Schweess Pipe | Gr.1 Gr.2 Gr.7 Gr.12 | ≥OD133 | ASTM B862 | |

| Tube (Russland) | BT1-0 | OD(3-114)×THK(0,5-10) ×≤ Längt 12000 | GOST 22879 | |

Chemesch Zesummesetzung

| Grad | Chemesch Zesummesetzung, Gewiicht Prozent (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Aner Elementer Max.jeweils | Aner Elementer Max.am Ganzen | |

| Gr 1 | 0,08 | 0.18 | 0,03 | 0,015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr 2 | 0,08 | 0,25 | 0,03 | 0,015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| gr4 | 0,08 | 0,25 | 0,03 | 0,015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| gr5 | 0,08 | 0.20 | 0,05 | 0,015 | 0,40 | 5,5-6,75 | 3.5-4.5 | - | - | - | - | 0.1 | 0.4 |

| gr7 | 0,08 | 0,25 | 0,03 | 0,015 | 0.30 | - | - | 0.12-0.25 | - | 0.12-0.25 | - | 0.1 | 0.4 |

| gr9 | 0,08 | 0.15 | 0,03 | 0,015 | 0,25 | 2,5-3,5 | 2.0-3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr 11 | 0,08 | 0.18 | 0,03 | 0.15 | 0.2 | - | - | 0.12-0.25 | - | - | - | 0.1 | 0.4 |

| Gr 12 | 0,08 | 0,25 | 0,03 | 0.15 | 0.3 | - | - | - | - | 0,6-0,9 | 0.2-0.4 | 0.1 | 0.4 |

| Gr 16 | 0,08 | 0,25 | 0,03 | 0.15 | 0.3 | - | - | 0.04-0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0,08 | 0.13 | 0,03 | 0,125 | 0,25 | 5.5-6.5 | 3.5-4.5 | - | - | - | - | 0.1 | 0.1 |

Kierperlech Eegeschaften

| Grad | Kierperlech Eegeschaften | ||||

| Tensile Kraaft Min | Yield Kraaft Min (0,2%, Offset) | Verlängerung an 2in oder 50mm Min (%) | |||

| ksi | MPa | ksi | MPa | ||

| Gr 1 | 35 | 240 | 20 | 138 | 24 |

| Gr 2 | 50 | 345 | 40 | 275 | 20 |

| gr5 | 130 | 895 | 120 | 828 | 10 |

| gr7 | 50 | 345 | 40 | 275 | 20 |

| gr9 | 90 | 620 | 70 | 483 | 15 |

| Gr 11 | 35 | 240 | 20 | 138 | 24 |

| Gr 12 | 70 | 483 | 50 | 345 | 18 |

| Gr 16 | 50 | 345 | 40 | 275 | 20 |

| Gr23 | 120 | 828 | 110 | 759 | 10 |