Titanium Hlau / Silk

Peb tuaj yeem muab tantalum hlau ntawm lub tshuab nqus hluav taws xob hluav taws xob melting thiab hmoov metallurgy tshuab, Lub hom phiaj ntawm tantalum hlau yog tsim los ntawm lub tshuab nqus hluav taws xob beam melting technology, nws muaj qhov purity siab.Capacitor qib tantalum hlau feem ntau yog tsim los ntawm cov hmoov hlau metallurgy, nws muaj ntau cov hlau tshwj xeeb.Tantalum hlau tau tsim los ntawm tantalum bar.Ua ntej ntawm tag nrho cov, dov tawm qhov tsim nyog loj ntawm tantalum bar, ntxuav lub tantalum bar, tshem tawm cov ntaub ntawv nto thiab roj paug, trimming lub tantalum bar thiab ntxuav dua, ces los ntawm stretching thiab annealing rau ntau zaus, nws thiaj li tau txais cov specifications ntawm cov neeg muas zaub. , los ntawm kev tu, straightening, winding, peb tuaj yeem tau txais cov xaim ncaj nraim los yog coil.Giant Hlau tshwj xeeb txoj kev dov, ncab txheej txheem, compression piv tswj, annealing kub thiab annealing lub sij hawm tswj yuav lav tantalum hlau muaj zoo heev mechanical zog, ua rau saum npoo du, huv si, tsis muaj roj, tsis muaj kab nrib pleb thiab burrs, tsis muaj teeb meem nyob ib ncig ntawm, thiab soj ntsuam nyob rau hauv 25 lub sij hawm magnification, nws tsis tas yuav dents thiab khawb, muaj zoo metallurgical qauv, thiaj li yuav xyuas kom meej qhov zoo ntawm tantalum hlau yog zoo dua lwm yam tuam txhab uas muag nyob rau hauv tib lub lag luam.

Ntxiv nrog rau muab cov ntshiab tantalum hlau, peb lub tuam txhab kuj muab tantalum alloy hlau.

Khoom siv:

Tantalum Niobium hlau (TaNb3, TaNb20, TaNb40)

Tantalum Tungsten hlau (Ta2.5W, Ta10W)

Txoj kab uas hla: 0.1 ~ 4mm

Txuj: ASTM B365

Puab: Ncaj, Coil

Status: Hard, Semi-hard, Mild

Daim ntawv thov

Capacitor qib tantalum hlau yog siv los ua tantalum electrolytic capacitor anode txhuas.tantalum hlau yog cov khoom tseem ceeb rau tantalum capacitor, tantalum capacitor yog qhov zoo tshaj plaws capacitor, txog 65% ntawm lub ntiaj teb tantalum siv hauv daim teb no.

Siv los tsim tantalum mesh.

Siv rau suture los them cov leeg nqaij, stitch paj hlwb thiab tendons, ntau lawm cov hlab ntsha stent, thiab lwm yam.

Siv los tsim lub tshuab nqus tsev kub kub rau cov khoom cua sov.

Siv rau lub tshuab nqus tsev electron emitting cathode qhov chaw, ion sputtering thiab txheej cov ntaub ntawv, thiab lwm yam.

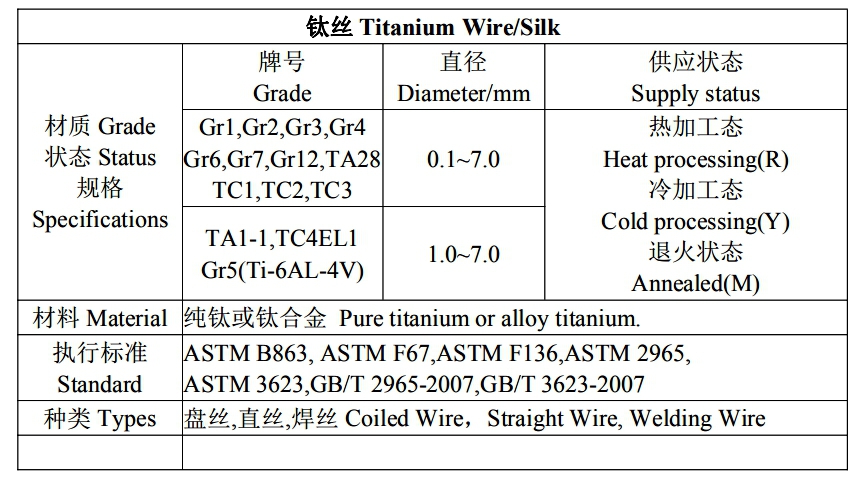

| Titanium Wire Diameters thiab Hom | ||||

| Txoj kab uas hla & hom | ||||

| Txoj kab uas hla | Hom | |||

| mm | nti | Coil | Spool | Ncaj |

| 0.05-0.78 Nws | 0.002-0.031 Nws | Y | Y | N |

| > 0.78 rau 3.25 | > 0.031 rau 0.128 | Y | Y | Y |

| > 3.25-6.00 Nws | > 0.128 rau 0.236 | Y | N | Y |

Txoj kab uas hla: +/- 0.05mm (+/- 0.002 ") lossis finer.Loj: 100mm - 300mm (3.9 "- 12").Ncaj Ntev: 300mm - 3000mm (12 "- 118")

| Qib | Specifications | ||

| AWS A5.16 | ASTM B863 Cov Khoom Siv Hluav Taws Xob | AMS | |

| Kev lag luam Ntshiab Titanium | ERTi-1,2,3,4 | ASTM B863 Gr1,2,3,4 | TIAB SA 4951 |

| ASTM F67 Gr1, 2, 3, 4 | TIAB SA 4921 | ||

| Ti 6Al-4V | ERTi-5 | ASTM B863 Gr5 | TIAB SA 4954 |

| Ti 6Al-4V Eli | ERTi-5 Eli | ASTM B863 Gr23 | TIAB SA 4956 |

| ASTM F136 1 | |||

| TSI 0.2 Pd | ERTi-7 | ASTM B863 Gr7 | - |

| Ti 3Al-2.5V | ERTi-9 | ASTM B863 Gr9 | - |

| Ti 0.3Mo-0.8Ni | ERTi-12 | ASTM B863 Gr12 | - |

Tshuaj muaj pes tsawg leeg

| Kev sib xyaw (%) | |||||||||||||

| Qib | Cov ntsiab lus tseem ceeb | Cov ntsiab lus impurity (≤) | |||||||||||

| Ta | Nb | Fe | Si | Ni | W | Mo | Ti | Nb | O | C | H | N | |

| Ta1 | Bal | — | 0.005 ib | 0.005 ib | 0.002 ib | 0.01 ib | 0.01 ib | 0.002 ib | 0.03 ib | 0.015 ib | 0.01 ib | 0.0015 Nws | 0.005 ib |

| Tau 2 | Bal | — | 0.03 ib | 0.02 ib | 0.005 ib | 0.04 ib | 0.03 ib | 0.005 ib | 0.1 | 0.02 ib | 0.01 ib | 0.0015 Nws | 0.005 ib |

| Taub 3 | Bal | 1.5 ~ 3.5 hli | 0.03 ib | 0.03 ib | 0.005 ib | 0.04 ib | 0.03 ib | 0.005 ib | — | 0.02 ib | 0.01 ib | 0.005 ib | 0.01 ib |

| TAB 20 | Bal | 17.0-23.0 Nws | 0.03 ib | 0.03 ib | 0.005 ib | 0.04 ib | 0.03 ib | 0.005 ib | — | 0.02 ib | 0.01 ib | 0.005 ib | 0.01 ib |

| TAB 40 | Bal | 35.0-42.0 Nws | 0.01 ib | 0.005 ib | 0.01 ib | 0.05 Nws | 0.02 ib | 0.01 ib | — | 0.02 ib | 0.01 ib | 0.015 ib | 0.01 ib |

| ua 2.5w | Bal | — | 0.01 ib | 0.005 ib | 0.01 ib | 2.0 ~ 3.5 | 0.01 ib | 0.002 ib | 0.1 | 0.01 ib | 0.01 ib | 0.0015 Nws | 0.01 ib |

| Ta 10 W | Bal | — | 0.01 ib | 0.005 ib | 0.01 ib | 9.0 ib ~ 11.0 Nws | 0.01 ib | 0.002 ib | 0.1 | 0.015 ib | 0.01 ib | 0.0015 Nws | 0. |

Mechanical zog

| xwm txheej | Tensile zog (Mp) | Elongation (%) |

| Mob me | 300-750 | 10 ~ 30 |

| Ib nrab tawv | 750-1250 Nws | 1 x 6 |

| Nyuaj | > 1250 | 1 x5 |

| TaNb3, TaNb20, cov khoom siv kho tshuab raws li lub Hoobkas ntsuas. | ||

Kev kam rau siab (mm)

| Txoj kab uas hla | Ua siab ntev |

| 0.1 ~ 0.2 hli | <0.005 |

| 0.2-0.5 hli | <0.007 |

| 0.5 ~ 0.7 hli | <0.010 |

| 0.7-1.5 hli | <0.015 |

| 1.5~ 2.0 | <0.020 |

| 2.0 ~ 3.0 | <0.030 Nws |

| 3.0 ~ 4.0 | <0.040 Nws |

Antioxidant brittleness

| Qib | Txoj kab uas hla (mm) | Antioxidant brittleness Tus naj npawb ntawm dabtsi yog khoov (≥) |

| Ta1 | 0.10-0.40 Nws | 3 |

| > 0.40 | 4 | |

| Tau 2 | 0.10-0.40 Nws | 4 |

| > 0.40 | 6 |

Coil hlau: Tom qab cua thiab parcel nrog pearl paj rwb (expandable polyethylene), ces packed nyob rau hauv ntoo rooj.

Ncaj hlau: ntim cov tantalum xaim rau hauv hnab yas thiab muab tso rau hauv lub thoob yas ncaj, ces ntim rau hauv rooj ntoo.