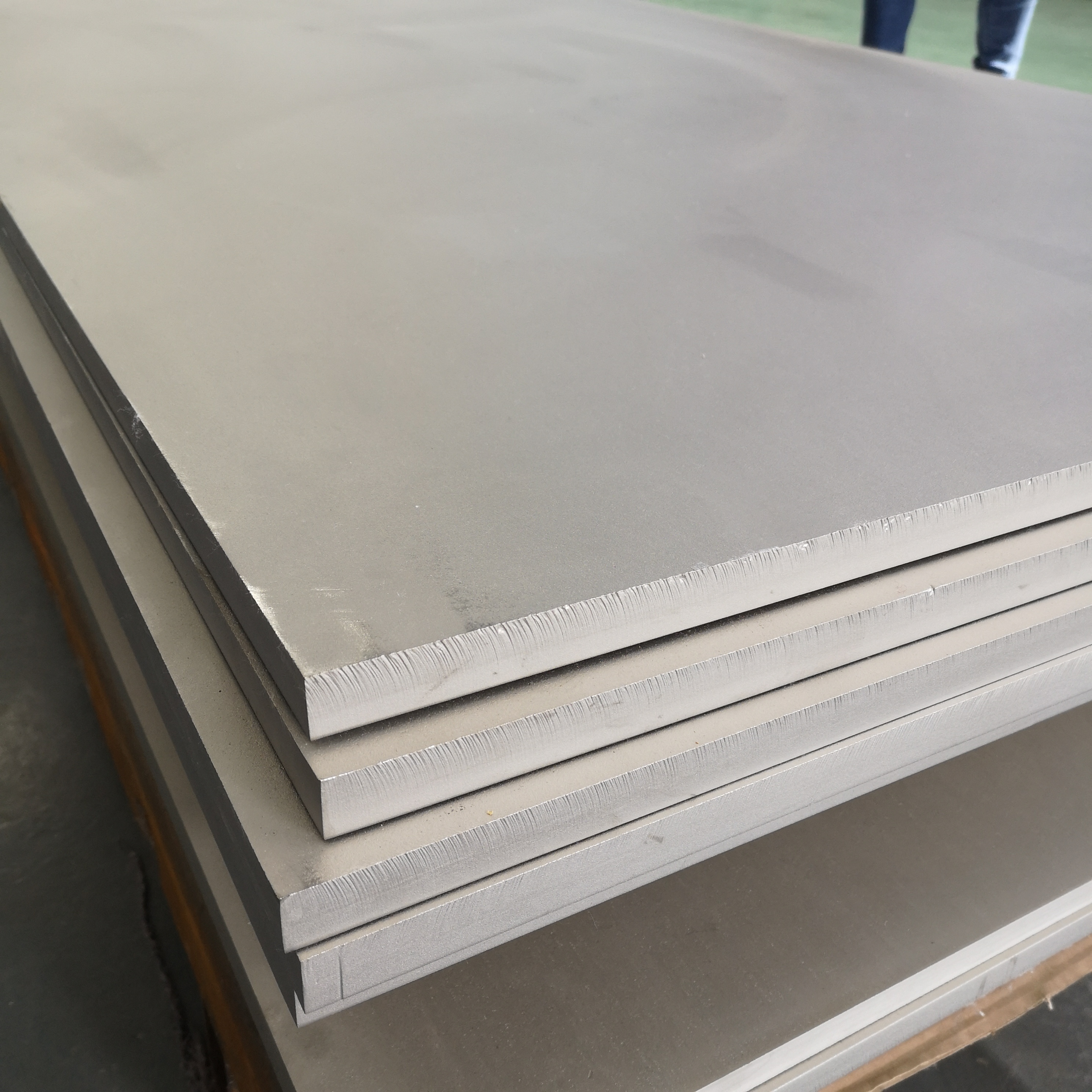

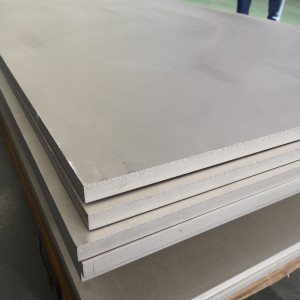

Titanium Sheet / Phaj

Cov Qib

Titanium Qib 1yog ib qho khoom siv tsis muaj zog, tsis tshua muaj zog titanium khoom uas muaj cov pa oxygen tsawg nrog cov ntawv muaj peev xwm;qib titanium no yog siv nyob rau hauv cov cua thav duab, tshav kub exchanges thiab desalination units.

Titanium Qib 2yog ib qho khoom siv tsis muaj zog, nruab nrab lub zog titanium khoom.Qib titanium no yog siv rau hauv cov huab cua thav ntawv, aircraft cav thiab marine qhov chaw;zoo weld muaj peev xwm thiab corrosion kuj yog nws cov yam ntxwv txawv.

Titanium Qib 3yog ib qho khoom siv tsis muaj zog, siab zog, titanium khoom muab kev tiv thaiv corrosion zoo thiab muaj peev xwm vuam zoo.Qib titanium no feem ntau yog siv rau hauv cov huab cua thav duab thiab dav hlau cav qhov chaw.

Titanium Qib 4yog lub zog siab tshaj plaws ntshiab unalloyed titanium khoom.Qib titanium no yog siv yuav luag tshwj xeeb rau huab cua thav duab, dav hlau cav qhov chaw, marine, phais kev cog hniav, hydraulic tubing.Zoo daim ntawv muaj peev xwm thiab corrosion kuj yog nws cov cim.

Titanium Qib 5 (6AL-4V)yog titanium alloyed khoom uas muaj 6% Aluminium thiab 4% Vanadium;yog ib yam khoom muaj zog nruab nrab.Qib titanium no feem ntau yog siv nyob rau hauv airframe thiab turbine engine qhov chaw;thiab siv nyob rau hauv kev phais implants.Cov ntaub ntawv qhia txog Titanium 6AL-4V ELI yog cov khoom siv titanium alloyed uas muaj 6% Aluminium thiab 4% Vanadium, ELI (Extra Low Interstitial).

6 AL-2 Sn-4 Zr-2Mo (6-2-4-2)yog cov khoom siv titanium alloyed uas muaj 6% Aluminium, 2% Tin, 4% Zirconium, 2% Molybdenum.

6 AL-6V-2 Sn (6-6-2)yog cov khoom siv titanium alloyed uas muaj 6% Aluminium, 6% Vanadium, 2% Tin.

5 AL-2.5 Sn & ELI (5-2.5)yog titanium alloyed khoom uas muaj 5% Aluminium thiab 2.5% Tin.Tsis tas li ELI (Extra Low Interstitial).

8 AL-1V-1Mo (8-1-1)yog cov khoom siv titanium alloyed uas muaj 8% Aluminium, 1% Molybdenum thiab 1% Vanadium.

15 v-3 Cr-4 AL-3 ZPO (15-3-4-3)yog cov khoom siv titanium alloyed uas muaj 15% Vanadium, 3% Chromium, 4% Aluminium, 3% Tin.

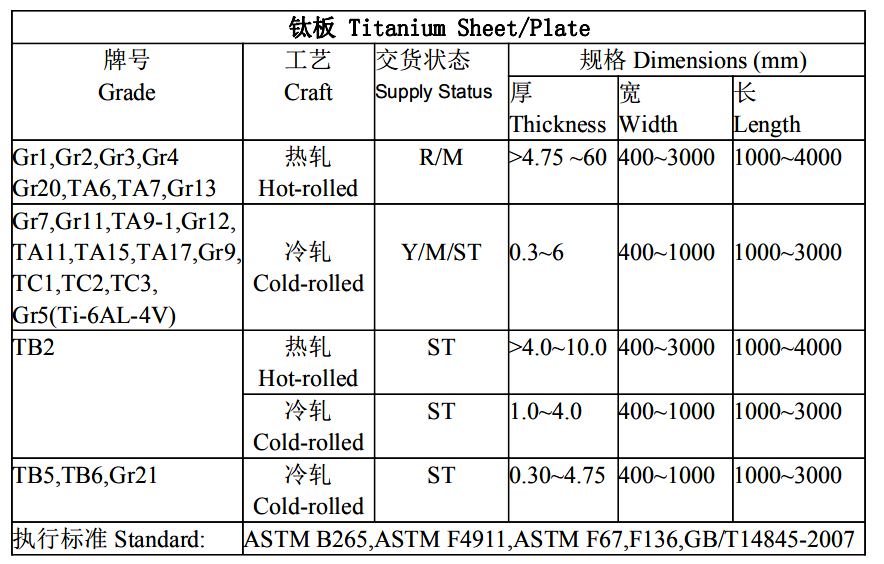

| Qib | xwm txheej | Specification | ||

| Gr1, Gr2, Gr4, Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 | Kub Rolled (R) Cold Rolled(Y) Annealed(M) Kev daws teeb meem (ST) | Thickness (hli) | Dav (mm) | Ntev (mm) |

| 0.3-60 | ≥400 | ≤ 6000 | ||

| Daim ntawv titanium | |||

| Thickness | Qib | ||

| .016 ib | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .020 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .025 ib | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .032 ib | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .040 ib | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .050 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .063 ib | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .071 ib | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .080 ib | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .090 ib | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .100 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .125 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

Nco tseg: Muaj ntau qhov ntau thiab tsawg, tsis yog txhua qhov ntau thiab tsawg pom muaj nyob hauv Tshuag.Thov hu rau peb kom kuaj xyuas muaj.

| AMS:AMS 2631, AMS 4901, AWS 4907, AMS 4911ASTM: ASTM B265 Gr23, ASTM B265 Gr5, ASTM B265 Gr2, ASTM B265 Gr4, ASTM F136, ASTM F67MIL-T:MIL-T-9046, MIL-T-9046 CP1EN:EN 10204.3, EN 1-204: 2005 3.1 NACE:NWS MR0175 ASME:ASME SB 265 |

| Qib | AMS/MIL specifications | ASTM Specs |

| Qib 1 | AMS-T-9046B CP4 AMS 4940 MIL-T-9046J CP4 | ASTM B265 Gr1 Sheet / phaj ASTM B337 Gr1 yeeb nkab ASTM B338 Gr1 tube ASTM B348 Gr1 bar ASTM F67 Gr1 Kev phais phais |

| Qib 2 | Qib 2 AMS-T-9046B CP3 AMS 4902 MIL-T-9046J CP3 TIAB SA 4941 TIAB SA 4942 AMS 4951 Vuam hlau | ASTM B265 Gr2 Sheet / phaj ASTM B337 Gr2 yeeb nkab ASTM B338 Gr2 tube ASTM B348 Gr2 bar ASTM F67 Gr2 Kev Txhaj Tshuaj Txhaum Cai |

| Qib 3 | AMS-T-9046B CP2 TIAB SA 4900 MIL-T-9046J CP2 | ASTM B265 Gr3 Sheet / phaj ASTM B337 Gr3 yeeb nkab ASTM B338 Gr3 tube ASTM B348 Gr3 bar ASTM F67 Gr3 Kev phais phais |

| Qib 4 | AMS-T-9046B CP1 AMS-T-9047A CP70 TIAB SA 4901 AMS 4921 MIL-T-9046J CP1 MIL-T-9047G CP70 | ASTM B265 Gr4 Sheet / phaj ASTM B337 Gr4 yeeb nkab ASTM B338 Gr4 tube ASTM B348 Gr4 bar ASTM F67 Gr4 Kev phais phais |

| Qib 7 | ASTM B265 Gr7 Sheet / phaj ASTM B337 Gr7 yeeb nkab ASTM B338 Gr7 tube ASTM B348 Gr7 bar |

| Qib | Teb Chaws Asmeskas Specs | ASTM Specs |

| Qib 5 6Al-4V | TIAB SA 4907 ELI TIAB SA 4911 TIAB SA 4928 UAS 4930 ELI AMS 4931 ELI Duplex xyoo TIAB SA 4963 TIAB SA 4965 TIAB SA 4967 TIAB SA 4985 TIAB SA 4991 TIAB SA 6931 TIAB SA 6932 MIL-T-9046J AB-1 MIL-T-9046J AB-2 (ELI) MIL-T-9046H Hom 3 Comp C MIL-T-9046H Hom 3 Comp D AMS-T-9046B AB-1 AMS-T-9046B AB-2 (ELI) MIL-T-9047G 6Al-4v MIL-T-9047G 6Al-4v (ELI) AMS-T-9047A 6Al-4v AMS-T-9047A 6Al-4v (ELI) | ASTM B265 Gr5 Sheet / phaj ASTM B348 Gr5 bar ASTM F136 Gr5 Implant Qib |

| Qib 9 3Al-2.5V | TIAB SA 4943 TIAB SA 4944 TIAB SA 4945 AMS-T-9046B AB-5 AMS-T-9047A 3Al-2.5V TSI MIL-T-9046J AB-5 MIL-T-9047 3Al-2.5V | ASTM B265 Gr6 Sheet / phaj ASTM B348 Gr6 bar |

| Qib 23 6Al-4V ELI | TIAB SA 4907 TIAB SA 4930 TIAB SA 6932 AMS-T-9046 AB-2 6AL-4V (ELI) AMS-T-9047 AB-2 6AL-4V (ELI) MIL-T-9046 AB-2 6AL-4V (ELI) MIL-T-9047 6AL-4V (ELI) | ASTM B265 Gr23 daim ntawv / phaj / sawb ASTM B348 Gr23 bar / ntawv nyiaj ASTM F136 Gr23 Implant Gra |

Tshuaj muaj pes tsawg leeg

| Qib | Tshuaj muaj pes tsawg leeg, qhov hnyav feem pua (%) | ||||||||||||

| C ≤ | O ≤ | N ≤ | H ≤ | Fe ≤ | Al | V | Pd | Ru | Ni | Mo | Lwm Yam Khoom Max.txhua | Lwm Yam Khoom Max.tag nrho | |

| Gr1 | 0.08 ib | 0.18 | 0.03 ib | 0.015 ib | 0.20 ib | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr 2 | 0.08 ib | 0.25 | 0.03 ib | 0.015 ib | 0.30 Nws | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 ib | 0.25 | 0.03 ib | 0.015 ib | 0.30 Nws | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr 5 | 0.08 ib | 0.20 ib | 0.05 Nws | 0.015 ib | 0.40 Nws | 5.5~6.75 ib | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 |

| gr 7 | 0.08 ib | 0.25 | 0.03 ib | 0.015 ib | 0.30 Nws | — | — | 0.12~0.25 | — | 0.12~0.25 | — | 0.1 | 0.4 |

| gr9 ua | 0.08 ib | 0.15 | 0.03 ib | 0.015 ib | 0.25 | 2.5~3.5 | 2.0~3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr 11 | 0.08 ib | 0.18 | 0.03 ib | 0.15 | 0.2 | — | — | 0.12~0.25 | — | — | — | 0.1 | 0.4 |

| Gr 12 | 0.08 ib | 0.25 | 0.03 ib | 0.15 | 0.3 | — | — | — | — | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr 16 | 0.08 ib | 0.25 | 0.03 ib | 0.15 | 0.3 | — | — | 0.04 ib~0.08 ib | — | — | — | 0.1 | 0.4 |

| Gr 23 | 0.08 ib | 0.13 | 0.03 ib | 0.125 Nws | 0.25 | 5.5~6.5 | 3.5~4.5 | — | — | — | — | 0.1 | 0.1 |

Lub cev muaj zog

| Qib | Lub cev muaj zog | ||||||

| Tensile zog Min | Yield zog (0.2%, offset) | Elongation hauv 50mm Min (%) | |||||

| ksi ua | MPa | Min | Max | ||||

| ksi ua | MPa | ksi ua | MPa | ||||

| Gr1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr 2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr4 | 80 | 550 | 70 | 483 ib | 95 | 655 | 15 |

| Gr 5 | 130 | 895 ib | 120 | 828 ib | — | — | 10 |

| gr 7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| gr9 ua | 90 | 620 | 70 | 483 ib | — | — | 15 |

| Gr 11 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr 12 | 70 | 483 ib | 50 | 345 | — | — | 18 |

| Gr 16 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr 23 | 120 | 828 ib | 110 | 759 ib | — | — | 10 |

Kev kam rau siab (mm)

| Thickness | Dav kam rau ua | ||

| 400-1000 | 1000-2000 | > 2000 | |

| 5.0 ~ 6.0 | ± 0.35 hli | ± 0.40 | ± 0.60 |

| 6.0-8.0 Nws | ± 0.40 | ± 0.60 | ± 0.80 hli |

| 8.0-10.0 Nws | ± 0.50 | ± 0.60 | ± 0.80 hli |

| 10.0-15.0 Nws | ± 0.70 hli | ± 0.80 hli | ± 1.00 |

| 15.0-20.0 Nws | ± 0.70 hli | ± 0.90 hli | ± 1.10 |

| 20.0-30.0 Nws | ± 0.90 hli | ± 1.00 | ± 1.20 |

| 30.0-40.0 Nws | ± 1.10 | ± 1.20 | ± 1.50 |

| 40.0 ~ 50.0 | ± 1.20 | ± 1.50 | ± 2.00 |

| 50.0 ~ 60.0 | ± 1.60 | ± 2.00 | ± 2.50 |