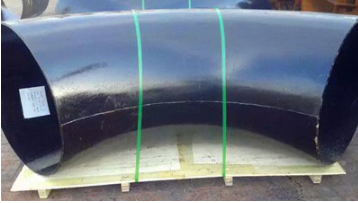

Luj tshib

Seamless Elbow Manufacturing Txheej txheem (Tshav kub dabtsi yog khoov & txias dabtsi yog khoov)

Ib txoj hauv kev zoo tshaj plaws rau kev tsim lub luj tshib yog siv kub mandrel dabtsi yog khoov los ntawm cov kav hlau ncaj.Tom qab cua sov cov yeeb nkab steel ntawm qhov kub siab, cov yeeb nkab raug thawb, nthuav dav, khoov los ntawm cov cuab yeej sab hauv ntawm mandrel ib kauj ruam.Thov kub mandrel dabtsi yog khoov tuaj yeem tsim tau ntau yam seamless luj tshib.Cov yam ntxwv ntawm mandrel dabtsi yog khoov yog muaj zog nyob ntawm qhov sib xyaw ua ke thiab qhov ntev ntawm mandrel.Kev siv qhov zoo ntawm lub luj tshib kub muaj xws li me me thickness sib txawv thiab muaj zog dabtsi yog khoov vojvoog dua li lwm yam dabtsi yog khoov hom.Meanwhile, siv dabtsi yog khoov es tsis txhob ntawm prefabricated khoov yuav txo tau tus naj npawb ntawm welds xav tau.Qhov no txo cov kev ua haujlwm uas yuav tsum tau ua thiab ua kom cov kav dej zoo thiab siv tau.Txawm li cas los xij, kev khoov txias yog cov txheej txheem los khoov cov yeeb nkab ncaj nraim ntawm qhov kub thiab txias hauv lub tshuab dabtsi yog khoov.Txias dabtsi yog khoov yog haum rau cov kav dej nrog ib txoj kab uas hla ntawm 17.0 mus rau 219.1 hli, thiab phab ntsa thickness 2.0 mus rau 28.0 hli.Qhov pom zoo khoov vojvoog yog 2.5 x Ua.Feem ntau ntawm lub vojvoog khoov ntawm 40D.Los ntawm kev siv txias khoov, peb tuaj yeem tau txais lub luj tshib me me, tab sis peb yuav tsum tau ntim cov khoom sab hauv nrog xuab zeb kom tsis txhob wrinkling.Khoov txias yog ib txoj kev khoov sai thiab pheej yig.Nws yog ib qho kev sib tw rau kev ua cov raj xa dej thiab tshuab qhov chaw.

Welded Luj Tshib Txheej Txheem (Me & Loj)

Welded luj tshib yog tsim los ntawm cov hlau phaj, yog li nws tsis yog seamless steel luj tshib.Siv cov pwm thiab nias lub phaj steel rau cov duab ntawm lub luj tshib, tom qab ntawd weld lub seam kom ua tiav lub luj tshib.Nws yog txoj kev tsim khoom qub ntawm lub luj tshib.Xyoo tsis ntev los no lub luj tshib me me yog yuav luag tsim los ntawm cov kav dej steel tam sim no.Rau lub luj tshib loj, piv txwv li, nws yog qhov nyuaj heev los tsim lub luj tshib tshaj 36 "OD los ntawm cov kav hlau.Yog li nws yog feem ntau ua los ntawm cov hlau phaj, nias lub phaj mus rau cov duab ntawm ib nrab lub luj tshib, thiab welding ob halves ua ke.Txij li thaum lub luj tshib yog welded nyob rau hauv nws lub cev, kev soj ntsuam ntawm lub vuam sib txuas yog tsim nyog.Feem ntau peb siv X-Ray tshuaj xyuas raws li NDT.

| Nominal yeeb nkab loj | Sab nraud txoj kab uas hla | Center to End | Center rau Center | Rov qab mus rau Faces | ||||||

| 45 ° luj tshib | 90 ° luj tshib | 180 ° Rov qab | ||||||||

| H | F | P | K | |||||||

| DN | INCH | Series A | Series B | LR | LR | SR | LR | SR | LR | SR |

| 15 | 1/2 | 21.3 | 18 | 16 | 38 | - | 76 | - | 48 | - |

| 20 | 3/4 | 26.9 ib | 25 | 16 | 38 | - | 76 | - | 51 | - |

| 25 | 1 | 33.7 ib | 32 | 16 | 38 | 25 | 76 | 51 | 56 | 41 |

| 32 | 11/4 | 42.4 ib | 38 | 20 | 48 | 32 | 95 | 64 | 70 | 52 |

| 40 | 11/2 | 48.3 ib | 45 | 24 | 57 | 38 | 114 | 76 | 83 | 62 |

| 50 | 2 | 60.3 | 57 | 32 | 76 | 51 | 152 | 102 | 106 | 81 |

| 65 | 21/2 | 76.1 (73) | 76 | 40 | 95 | 64 | 191 | 127 | 132 | 100 |

| 80 | 3 | 88.9 ua | 89 | 47 | 114 | 76 | 229 | 152 | 159 | 121 |

| 90 | 31/2 | 101.6 ib | - | 55 | 133 | 89 | 267 | 178 | 184 | 140 |

| 100 | 4 | 114.3 ib | 108 | 63 | 152 | 102 | 305 | 203 | 210 | 159 |

| 125 | 5 | 139.7 ib | 133 | 79 | 190 | 127 | 381 ib | 254 | 262 | 197 |

| 150 | 6 | 168.3 ib | 159 | 95 | 229 | 152 | 457 ib | 305 | 313 | 237 |

| 200 | 8 | 219.1 ib | 219 | 126 | 305 | 203 | 610 | 406 | 414 ib | 313 |

| 250 | 10 | 273.0 Nws | 273 | 158 | 381 ib | 254 | 762 ib | 508 | 518 | 391 ib |

| 300 | 12 | 323.9 ib | 325 | 189 | 457 ib | 305 | 914 ib | 610 | 619 ib | 467 ib |

| 350 | 14 | 355.6 ib | 377 ib | 221 | 533 ib | 356 | 1067 ib | 711 ib | 711 ib | 533 ib |

| 400 | 16 | 406.4 ib | 426 | 253 | 610 | 406 | 1219 | 8 13 | 8 13 | 610 |

| 450 | 18 | 457.2 ib | 478 ib | 284 | 686 ib | 457 ib | 1372 ib | 914 ib | 914 ib | 686 ib |

| 500 | 20 | 508.0 ib | 529 ib | 316 | 762 ib | 508 | 1524 ib | 1016 | 1016 | 762 ib |

| 550 | 22 | 559 ib | - | 347 ib | ib 838 | 559 ib | Nco tseg: | |||

| 600 | 24 | 610 | 630 | 379 ib | 914 ib | 610 | ||||

| 650 | 26 | 660 | - | 410 | 991 ib | 660 | ||||

| 700 | 28 | 711 ib | 7 20 | 442 ib | 1067 ib | 711 ib | ||||

| 750 | 30 | 762 ib | - | 473 ib | 1143 ib | 762 ib | ||||

| 800 | 32 | 8 13 | 820 | 505 | 1219 | 8 13 | ||||

| 850 | 34 | 864 ib | - | 537 ib | 1295 ib | 864 ib | ||||

| 900 | 36 | 914 ib | 9 20 | 568 ib | 1372 ib | 914 ib | ||||

| 950 ua | 38 | 965 ib | - | 600 | 1448 ib | 965 ib | ||||

| 1000 | 40 | 1016 | 1020 | 631 ib | 1524 ib | 1016 | ||||

| 1050 | 42 | 1067 ib | - | 663 ib | 1600 | 1067 ib | ||||

| 1100 | 44 | 1118 | 1120 | 694 ib | 1676 ib | 1118 | ||||

| 1150 | 46 | 1168 | - | 726 ib | 1753 ib | 1168 | ||||

| 1200 | 48 | 1220 | 1220 | 758 ib | 1829 | 1219 | ||||

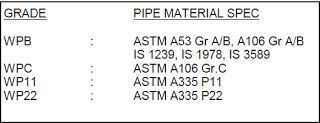

ASTM A 234, ASTM A 234

Qhov kev qhia tshwj xeeb no npog wrought carbon steel & alloy steel fittings ntawm seamless thiab welded tsim.Tshwj tsis yog seamless lossis welded kev tsim kho tau teev nyob rau hauv kev txiav txim, ob qho tib si yuav raug muab tso rau ntawm qhov kev xaiv ntawm tus neeg muag khoom.Tag nrho cov welded tsim fittings raws li tus qauv no yog muab nrog 100% radiography.Raws li ASTM A234, ntau qib muaj nyob ntawm cov tshuaj muaj pes tsawg leeg.Kev xaiv yuav yog nyob ntawm cov khoom siv yeeb nkab txuas nrog cov fittings no.

| Tensile Requirements | WPB | WPC, WP11CL2 | WP11CL1 | WP11CL3 |

| Tensile zog, min, ksi [MPa] | 60-85 : kuv | 70-95 : kuv | 60-85 : kuv | 75-100 : kuv |

| (0.2% offset los yog 0.5% extension-under-load) | [415-585] | [485-655] | [415-585] | [520-690] |

| Yield zog, min, ksi [MPa] | 32 | 40 | 30 | 45 |

| [240] | [275] | [205] | [310] |

Qee cov qhab nia muaj nyob rau hauv qhov kev qhia tshwj xeeb no thiab cov khoom sib txuas txuas nrog cov yeeb nkab specification yog teev hauv qab no:

ASTM A403 Cov khoom lag luam

Qhov kev qhia tshwj xeeb no suav nrog ob chav kawm dav dav, WP & CR, ntawm wrought austenitic stainless hlau fittings ntawm seamless thiab welded tsim.

Class WP fittings yog tsim los rau cov kev cai ntawm ASME B16.9 & ASME B16.28 thiab muab faib ua peb pawg raws li hauv qab no:

- WP - SManufactured los ntawm seamless khoom los ntawm seamless txoj kev ntawm kev tsim khoom.

- WP - W Cov fittings no muaj cov welds thiab tag nrho cov welds ua los ntawm cov chaw tsim khoom haum nrog rau pib cov yeeb nkab vuam yog tias cov yeeb nkab tau welded nrog ntxiv cov khoom muab tub lim yog radiographed.Txawm li cas los xij tsis muaj hluav taws xob ua tiav rau cov yeeb nkab pib vuam yog tias cov yeeb nkab tau welded yam tsis muaj qhov sib ntxiv ntawm cov khoom muab tub lim.

- WP-WX Cov fittings no muaj cov welds thiab tag nrho cov welds txawm yog tsim los ntawm cov chaw tsim khoom haum lossis los ntawm cov chaw tsim khoom pib yog radiographed.

Class CR fittings yog tsim los rau cov kev cai ntawm MSS-SP-43 thiab tsis tas yuav tsum tau kuaj xyuas.

Raws li ASTM A403 ntau qib muaj nyob ntawm cov tshuaj muaj pes tsawg leeg.Kev xaiv yuav yog nyob ntawm cov khoom siv yeeb nkab txuas nrog cov fittings no.Qee cov qhab nia muaj nyob rau hauv qhov kev qhia tshwj xeeb no thiab cov khoom sib txuas txuas nrog cov yeeb nkab specification yog teev hauv qab no:

ASTM A420 1

Qhov kev qhia tshwj xeeb no suav nrog wrought carbon steel thiab alloy steel fittings ntawm seamless & welded tsim tsim los siv rau qhov kub thiab txias.Nws npog plaub qib WPL6, WPL9, WPL3 & WPL8 nyob ntawm cov tshuaj muaj pes tsawg leeg.Fittings WPL6 raug kuaj ntawm qhov kub - 50 ° C, WPL9 ntawm -75 ° C, WPL3 ntawm -100 ° C thiab WPL8 ntawm -195 ° C kub.

Cov kev ntsuas siab tso cai rau fittings yuav raug xam raws li cov yeeb nkab ncaj seamless raws li cov kev cai tsim nyob rau hauv seem siv ntawm ASME B31.3.

Cov yeeb nkab phab ntsa tuab thiab cov khoom siv yuav tsum yog qhov uas cov fittings tau raug yuam kom siv, lawv tus kheej ntawm cov fittings yog nyob rau ntawm qhov ntsuas ntsuas ntsuas.

| Hlau No. | Hom | Tshuaj muaj pes tsawg leeg | ||||||||||||

| C | Si | S | P | Mn | Cr | Ni | Mo | Lwm yam | ovb ua | os | xib d5 | HB | ||

| WPL6 | 0.3 | 0.15-0.3 Nws | 0.04 ib | 0.035 ib | 0.6-1.35 Nws | 0.3 | 0.4 | 0.12 | Cb: 0.02; V: 0.08 | 415-585 : kuv | 240 | 22 | ||

| WPL9 | 0.2 | 0.03 ib | 0.03 ib | 0.4-1.06 Nws | 1.6-2.24 Nws | 435-610 : kuv | 315 | 20 | ||||||

| WPL3 | 0.2 | 0.13-0.37 Nws | 0.05 Nws | 0.05 Nws | 0.31-0.64 Nws | 3.2-3.8 | 450-620 : kuv | 240 | 22 | |||||

| WPL8 | 0.13 | 0.13-0.37 Nws | 0.03 ib | 0.03 ib | 0.9 | 8.4-9.6 | 690-865 : kuv | 515 | 16 | |||||

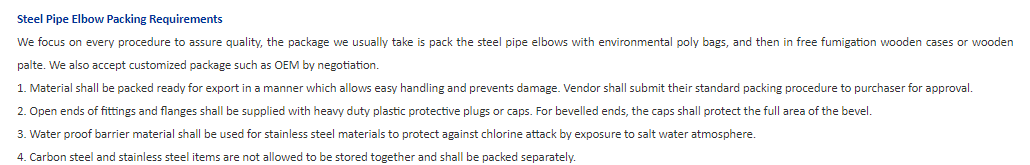

Lub teeb Oiling, Dub Painting, Galvanizing, PE / 3PE Anti-corrosion Txheej

Ntim hauv Ntoo Cabins / Ntoo Tais