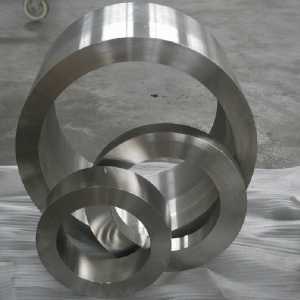

apo Titanium

Hana ʻia nā apo titanium nui e ka mīkini mīkini wili nui, hiki ke hoʻokō ʻia nā apo liʻiliʻi ma ka mīkini forging.Ma ke ʻano he hui me ka ʻoi aku o 20 mau makahiki o ka ʻike hana, loaʻa iā mākou kahi ʻano o ke kaʻina hana forging koʻikoʻi a me ka manual hana, me nā ʻanuʻu wela, ka manawa wela a me ka manawa mālama wela.Ua hōʻoia ka 35MN a me 16MN i ka mīkini forging wikiwiki i ka nui o ka forging i ka pae wela kūpono, a hoʻololi i ke ʻano kino kūloko o nā apo titanium.Ua hoʻomaikaʻi nui ʻia ka maikaʻi o kā mākou huahana.

Ma kahi o ke apo titanium, hāʻawi pū mākou i ka hana o ka titanium disc, titanium block etc.

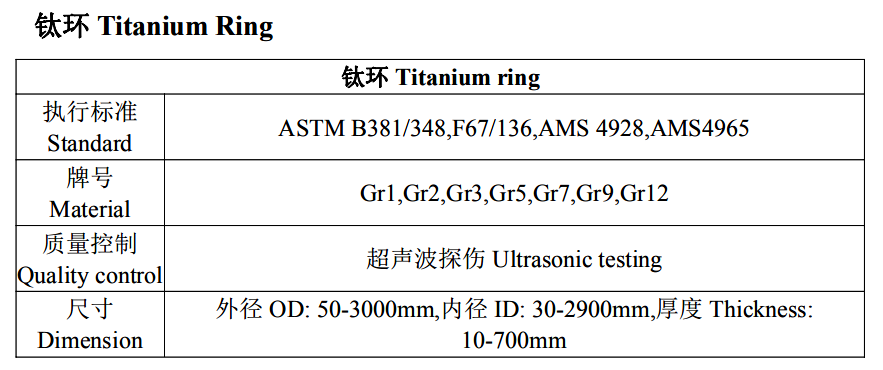

| inoa mea kūʻai | apo Titanium |

| Nui | OD (max3000mm)×ID(max2900mm)×lōʻihi(ka lōʻihi loa 1000mm) |

| Papa | TA1/TA2/TA5/TA6/TA9/TA10/TA15/TA19/TC1/TC2/TC4/TC11/ GR1/GR2/GR5/GR7/GR9/GR12/GR23 |

| Nā kūlana | ASTM B381/348,F67/136,AMS4928,AMS4965,AMS,MIL,DIN,BS,JIS,GB / T,ISOetc |

| ʻO ka mānoanoa | 4.51g / cm3 Kiʻekiʻe hana hana ʻoihana forging, gr12 Titanium forged rolling apo |

| ʻenehana | ʻO ka hoʻopaʻa ʻana, ka ʻōwili ʻana, ka wili ʻana i ka hana kiʻekiʻe e hoʻoheheʻe ana i ka GR12 titanium forging rolling apo |

| ʻAno | ʻO ke kaʻina o ka ʻōwili apo ʻole ʻia e ʻoki i ka lua i loko o ka mea i hoʻopaʻa ʻia a ʻōwili ʻia i loko o ke apo lahilahi. Hoʻohālikelike ʻia i ka pā kī a i ʻole ka kuʻekuʻe wāwae, ʻo ke apo i ʻōwili ʻia e hāʻawi i kahi hoʻomaikaʻi concentric me kahi apo maʻemaʻe. Ring kiʻekiʻe hana hana ʻoihana GR12 titanium forged rolling apo |

| Palapala noi | 1. Electroplating;2.ʻenehana a me ka ʻenehana petrochemical;3.Lapaʻau kiʻekiʻe hana ʻoihana forging GR12 titanium forging rolling apo |

ASTM B381/348,F67/136,AMS4928,AMS4965

haku mele ʻana

| Papa | ʻO ka haku mele, ka pākēneka kaumaha (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Nā mea ʻē aʻe Max.kēlā me kēia | Nā mea ʻē aʻe Max.huina | |

| ʻO Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 |

| ʻO Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5~6.75 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | 0.12~0.25 | — | 0.12~0.25 | — | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5~3.5 | 2.0~3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | — | — | 0.12~0.25 | — | — | — | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | — | — | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | 0.04~0.08 | — | — | — | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5~6.5 | 3.5~4.5 | — | — | — | — | 0.1 | 0.1 |

Nā waiwai kino

| Papa | Nā waiwai kino | |||||

| Ka ikaika tensile Min | Hua ikaika Min (0.2%, offset) | Elongation ma 4D Min (%) | Hoemi o Wahi Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| ʻO Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| ʻO Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |