ASTM A234kila maʻamaupaipu paipuua hoʻohana nui ʻia i nā ʻōnaehana pipeline, loaʻa i ke kila kalapona a me nā mea hao hao.

He aha ke ano o na paipu kila?

Hana ʻia ka paipu kila me ke kila kalapona a i ʻole ka paipu kila kila, nā papa, nā profiles, i kahi ʻano i hiki ke hana i kahi hana (E hoʻololi i ke kuhikuhi wai a i ʻole ka helu) i nā ʻōnaehana pipeline. ʻO ka hapa nui o kēia mau mea e pili ana i ka kuʻe lima kila (45 a i ʻole 90 degere bend), tee, reducer (concentric or eccentric reducer), keʻa, nā pāpale, nipple, flanges, gasket, studs a me nā mea ʻē aʻe.

No nā hana ʻoihana, ma nā ʻōnaehana pipeline maʻamau pono mākou e hoʻololi i ke kuhikuhi o ka hoʻouna ʻana; Hoʻoponopono i nā wai (ʻaila a me ke kinoea, wai, slurry) kahe kahe; Wehe a pani paha i nā paipu, a pēlā aku no ka hoʻopau ʻana i kēia mau hana, e hoʻohana ʻia nā paipu kila.

He aha ka ASTM A234 WPB?

ʻO ka ASTM A234 ka kikoʻī maʻamau no nā paipu paipu kila e pili ana i ke kila kalapona a me nā mea kila kila no nā lawelawe wela a me ke kiʻekiʻe. Hoʻopili ia i nā mea kila o nā ʻano wili ʻole a welded. Hoʻohana ʻia nā mea hoʻopili Pipe Steel i nā paipu kaomi a me nā mea hana moku. ʻO kēia mau mea pono me ke kila make, forgings, bars, plates, seamless a i ʻole HFW (fusion welded) huahana paipu, me ka mea hoʻopiha metala i hoʻohui ʻia.

Loaʻa i ka ASTM A234 nā kila kalapona i hana ʻia a me nā mea kila kila o ka hana ʻole a welded i uhi ʻia e ka loiloi hou o ASTM B16.9, B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, a me MSS. -SP-97. etc.

E like me kā mākou e ʻike ai, hoʻohana ʻia nā mea hoʻopili paipu kila ASTM A234 i ka paipu kaomi a me ka hana ʻana i nā moku kaomi, no nā lawelawe ma nā mahana haʻahaʻa a kiʻekiʻe. ʻO nā mea pono i loko o kēia maʻamau he kila make, forgings, bars, plates, seamless or fusion-welded tubular products with filler metal added.

Ma kēia maʻamau ka uhi ʻana i ka kikoʻī o nā kuʻekuʻe, nā tees, nā mea hoʻemi, nā pāpale a me ke keʻa, ʻo ia ka mea maʻamau e hoʻohana i nā hopena welding butt.

ʻO ASTM A234 nā ana paipu kila

Nā Kūlana: ANSI / ASME B16.9, B16.28, MSS-SP-43.

Ke Anawaena o waho: 1/2" a 48"

Mānoanoa: SCH 10, sch 20, SCH 40, SCH STD, SCH 80, SCH XS, SCH 160, SCH XXS etc.

ʻO nā ʻano paipu kila i hana ʻia ma ka forged, threaded, butt weld, a seamless.

Nā papa ma ASTM A234:

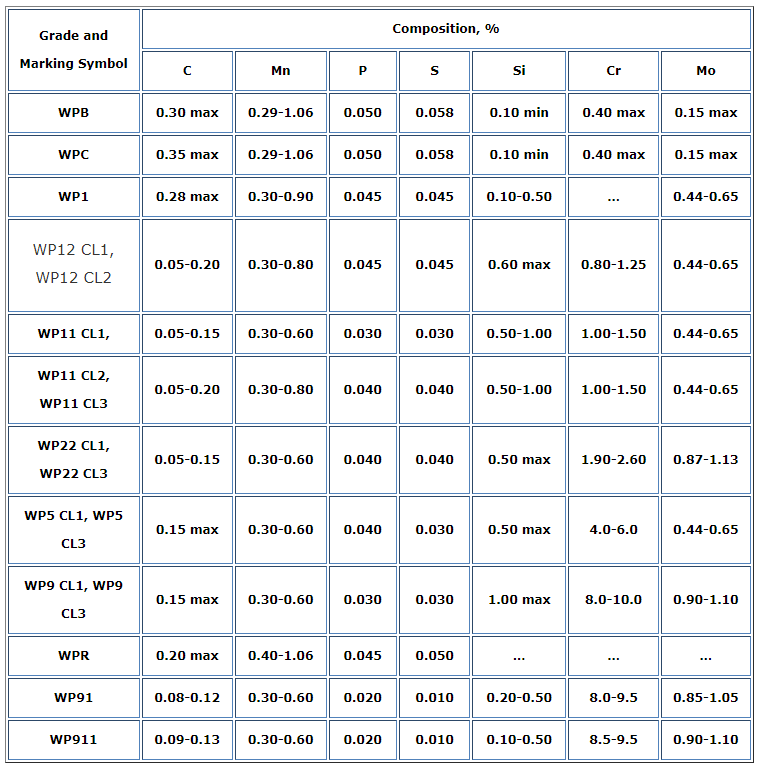

He nui nā mākau ASTM A234, e like me WPB, WPC, WP5, WP9 WP11, WP12, WP22, WP91 a pēlā aku.

I kēia mau pae maʻamau ʻo WPB ka mea maʻamau i hoʻohana ʻia no nā pipelines wela a me ke kiʻekiʻe. W 'o ia ho'i ka weldable, P 'o ia ho'i ke kaomi, B 'o ia ka papa b, e nānā i ka li'ili'i loa o ka ikaika.

ʻO ke kumu kumu o ka ASTM A234 WPB nā paipu kila mai ka paipu kila, e like me ASTM A106 Gr.B a me C. No ka pā kila, e like me ASTM A285 Gr.C, ASTM A516 Gr 70, ASTM A572 etc.

ʻO ASTM A234 WPB paipu kila e hoʻopili ana i nā mea kemika a me nā hiʻohiʻona mechanical:

1) He 0.35% ka nui o nā lako WPB mai nā paipu kila a i ʻole nā papa.

2) Ke hoʻopaʻa ʻana i nā mea pono ʻO ka maʻiʻo carbon 0.35% ka nui a me ka ʻike Silicon 0.35% ka nui, ʻaʻole ka liʻiliʻi.

3) No kēlā me kēia hōʻemi o 0.01 o ka maʻiʻo Carbon, hoʻonui ka nui o ka manganese i ka 0.06%, a hiki i ka 1.35% kiʻekiʻe no Mn.

4) Copper, Nickel, Niobium a me Molybdenum huina maʻiʻo ʻaʻole e oi aku ma mua o 1.00%.

5) ʻAʻole ʻoi aku ka nui o ka Niobium + Molybdenum i ka 0.32%.

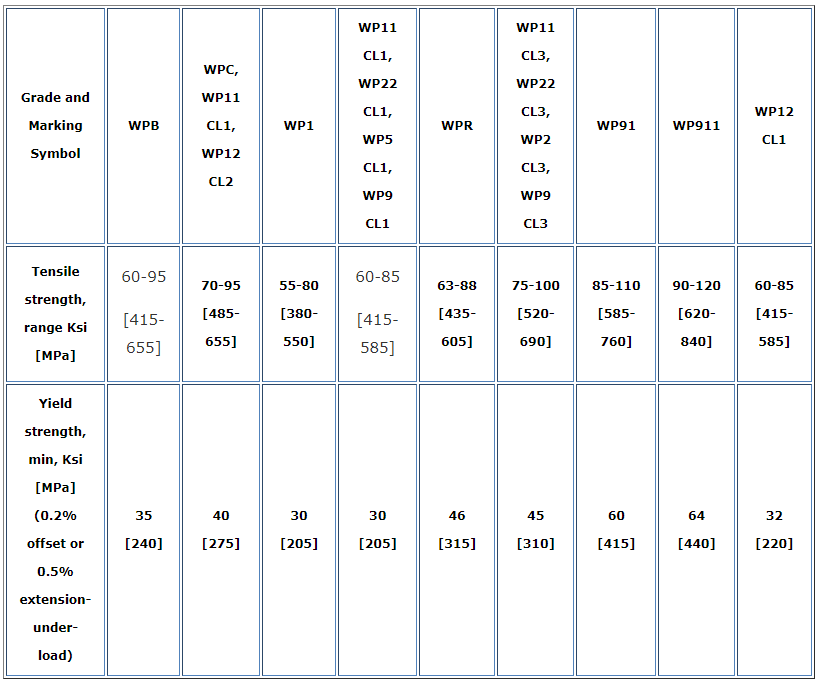

Mechanical waiwai o ASTM A234 WPB paipu paipu:

Ikaika U'i 60,000 pis 415 Mpa

ʻO ka ikaika 35,000 psi 240 Mpa

Nā Paʻi Paʻi: 150LBS, 300LBS, 600LBS, 900LBS, 1500LBS, 2000LBS, 3000LBS a 9000LBS.

Loaʻa i ka ASTM A234 nā paipu paipu ʻole a welded:

No ka paipu kila maʻemaʻe e pili ana i nā mea pono mai nā paipu kila maʻemaʻe a me nā paipu; No laila, uhi nā paipu kila kila i nā mea pono mai nā paipu kila welded.

E hoomanaoia,

ʻAʻole uhi ʻia ka kikoʻī ASTM A234 i nā mea hoʻoheheʻe hoʻoheheʻe a i ʻole nā mea hana i hana ʻia mai ka hoʻoheheʻe ʻana.

ʻO nā kaʻina hana hana ʻana i nā paipu kila:

ʻO nā kaʻina hana no nā paipu paipu e pili ana i ka hana forging a me ka hana ʻana. E like me ke kaomi ʻana, hammering, piercing, extruding, upsetting, rolling, bending, fusion welding and machining. A i ʻole nā kaʻina hana o ka hui ʻana o ʻelua a ʻoi aku paha o kēia mau hana.

I ka wā o ka hana ʻana i nā paipu kila, e ʻike ʻia nā hana ma lalo nei:

1) ʻAʻole hana ʻia nā hemahema ʻino, ʻaʻole e hana ʻia nā hemahema.

2) Ma hope o ka hana ʻana a i ʻole ka hana ʻana i nā mea pono i kahi mahana kūpono, e hoʻomaha ʻia ma nā wahi kūpono i kahi mahana ma lalo o ka pae koʻikoʻi. ʻAʻole e hana ʻia nā hemahema i ka wā o nā kaʻina hana hoʻomaha. ʻAʻole ʻoi aku ka wikiwiki o ka hoʻoluʻu ma mua o ka lewa.

3) E hana ʻia ka nānā kūpono ma hope o ka hana ʻana. (Hydrostatic test, hardness test, tensile test etc.)

ʻO nā māka paipu kila kila ma ASTM A234

Hoʻopili ʻia ka paipu kila kila me nā mea hoʻohui e like me Chrome, Molybdenum, Nickel alloy, Hastelloy alloy, Monel, Inconel, a me nā mea ʻē aʻe. Hoʻohana nui ʻia ia i nā pipeline aila a me ka hau, nā ʻoihana kemika, nā mea kanu mana, nā kahua nuklea, a ma nā kūlana kikowaena.

ʻO nā mea hoʻopili paipu kila hui pū kekahi me nā mea hoʻopili buttweld, nā kila kila lōʻihi radius piʻo, nā mea i hoʻopaʻa ʻia i ke kila kila a pēlā aku.

Hoʻohana ʻia nā mea hoʻohui kila buttweld i ka maʻamau ASTM A234, loaʻa nā māka WP1, WP5, WP11, WP12, WP22, WP23 a me WP91. Papa papa ma CL1, CL2, CL3.

ʻO ka ASTM A234 nā paipu kila kila e pili ana i nā kuʻekuʻe kila i ka lōʻihi a me ka pōkole radius, ke kila kila eccentric & concentric reducer, nā pāpale kila kila a me nā keʻa, nā hui ʻana o ke kila, nā kāʻei kila, nā nipples kila, nā pāpale kila a me nā ʻano ʻē aʻe. Loaʻa iā ia nā ʻano seamless, welded a fabricated.

No nā mea hoʻopili kila kila, hoʻohana ia i ka maʻamau ASTM A182 e pili ana i nā flanges paipu kila. Mea maʻamau ma ASTM A182 F1, F5, F9, F11 Papa 1, F12 Papa 1, F22 Papa 1 ETC.

Hoʻohui Kimia

Nā Koina Tensile

Ka manawa hoʻouna: Sep-05-2022