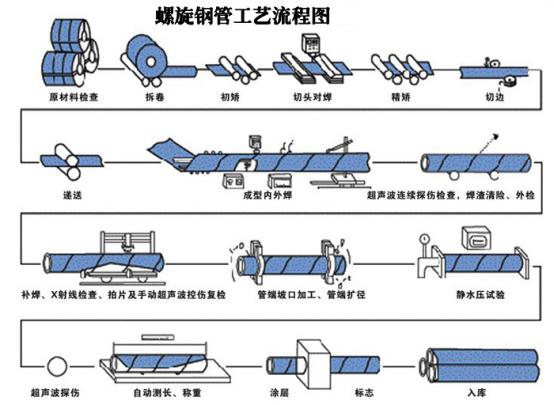

Ajija irin pipejẹ okun adikala bi ohun elo aise, nigbagbogbo imudọgba extrusion gbona, ilana alurinmorin apa meji-apa okun alaifọwọyi welded ajija okun irin pipe awọn ilana iṣelọpọ akọkọ jẹ bi atẹle:

Production ilana ti ajija, irin paipu

1. Ṣiṣayẹwo igbimọ ṣiṣi silẹ: Lẹhin titẹ laini iṣelọpọ awo ti o ṣii, idanwo ultrasonic kikun akọkọ.

2. Ipele milling: Awọn alapin irin anvil ẹrọ ki awọn atilẹba curl, ati ki o si nipasẹ awọn eti milling ẹrọ fun meji-apa, irin milling, ki lati pade awọn ibeere ti awọn iwọn awo, awo eti parallelism ati groove apẹrẹ.

3. irẹrun igbáti: awọn irin awo gbóògì ila pẹlú awọn lode eti ti ajija ọmọ-sinu kan tube.

4. apọju gige: alurinmorin arc submerged ti apa meji-meji nipa lilo imọ-ẹrọ to ti ni ilọsiwaju si iṣaju iṣaju, alurinmorin inu, alurinmorin ita. Ion ẹsẹ ge to sipesifikesonu ipari welded ajija pipe lilo ati be be lo.

5. Ayẹwo wiwo: nipasẹ awọn oṣiṣẹ ọjọgbọn ati imọ-ẹrọ si diẹ ninu awọn ipilẹ ipilẹ lati ṣayẹwo.

6. Iwari flaw ultrasonic: inu ati ti ita weld ati weld ni ẹgbẹ mejeeji ti ohun elo ipilẹ 100% ayewo.

7. X-ray erin: ti abẹnu ati ti ita welds 100% X-ray ise TV ṣayẹwo image processing eto lati rii daju wipe awọn lilo ti erin ifamọ.

8. Idanwo titẹ: ajija irin pipe hydrostatic igbeyewo ẹrọ-nipasẹ-root igbeyewo lati rii daju wipe awọn titẹ paipu pade awọn ti a beere awọn ajohunše.

9. chamfering alapin ori: ajija, irin pipe ayewo ti gbe jade lẹhin ti awọn paipu opin processing, lati pade awọn ibeere ti paipu opin beveling iwọn

10. Ipari ayewo: ultrasonic ati X-ray erin lẹẹkansi ati ajija, irin paipu dopin se patiku se ayewo, ṣayẹwo ti o ba ti nibẹ ni o wa isoro ati alurinmorin pipe pari awọn abawọn.

11. oiled siṣamisi: ajija irin pipe lẹhin ti o ti kọja won oiled lati se ipata, ati gẹgẹ bi olumulo awọn ibeere fun siṣamisi.

Akoko ifiweranṣẹ: Jun-22-2022