Waowa Steel Paipa Tukore

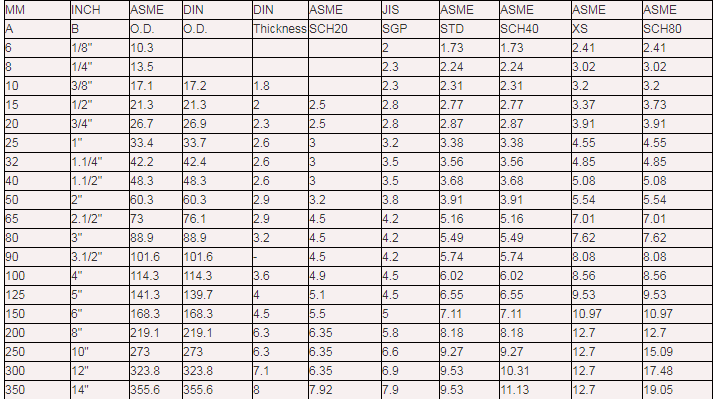

He mea hanga mai i te maitai porowhita totoka te paipa maitai kore'pire'ka whakamahanahia, ka panaia, ka kumea ranei ki runga i tetahi ahua kia hanga ra ano te maitai hei ngongo tuwhera.Ka oti te putorino tuitui ki nga tohu ine me te matotoru pakitara mai i te 1/8 inihi ki te 32 inihi OD.Wao Wao Paipa Tutoo / Tubes Waro maitai he koranu he rino me te waro.Ko te ōrau o te waro i roto i te maitai e pa ana ki te pakeke, te kaha o te elasticity me te ductility o te waro maitai.Ko te putorino waro paipa, he rino rino totoka ranei ka mahia mai i te ngongo capillary i roto i te rua, katahi ka puta mai te waea wera-whakataka, matao, makariri ranei.He waahi nui te putorino waro waro i roto i te umanga maitai o Haina.He putorino waro maitai putorino he ngongo porowhita, he putorino miihini tapahi putorino ki te tapahi mo te 1 m te roa o te watea, ka tukuna ma te whakamahana oumu whitiki kawe.Ka whangaia te pire ki roto i te oumu whakamahana, ko te pāmahana he 1200 nga nekehanga Celsius.Ko te hinu he hauwai, he acetylene ranei.Ko te whakahaere i te pāmahana oumu te take matua.I puta mai te ngongo porowhita ki te wero i te miihini na te pehanga hau.I te nuinga o te wa ko te whiunga noa ake ko te miihini hurihuri pukapuka miihini, he pai te whakaputanga teitei, te kounga hua, te roha kohao diameter nui, ka taea te kakahu i nga momo rino.Ko te poka, te ngongo porowhita i runga i te toru-roira ripeka okeoke, okeoke, tangohanga ranei.Ka ruia atu te ngongo i muri i te rahinga.Te whakahiatotanga ma te tere tere tere huri i nga rua ki roto i te pire hei hanga ngongo.Te diameter paipa ma te mira rahi hei whakatau i te roa o te diameter wiri.I muri i te putorino i roto i te rahinga ki te pourewa meangiti, meangiti i te rehu wai, maitai i muri i te meangiti, kia tika.I muri i te whitiki rino i tukuna mai e te miihini whakamatautau whakarewa (he whakamatautau pehanga ranei) mo te whakamatautau o roto.Mena ka pakaru te paipa o roto, ka kitea nga mirumiru me etahi atu raruraru.I muri i te putorino engari ano hoki na roto i te kowhiringa a-ringa mana kounga.Te kounga maitai, te whakamahi i nga nama peita rehu, nga whakaritenga, te nama rota whakaputa.Ma te warou ki roto i te whare putunga.

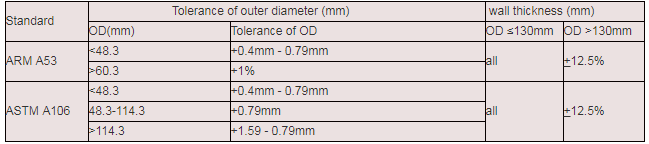

Te matotoru o te pakitara o te paipa kore

Te Whakaaetanga o te Diameter o waho me te matotoru o te pakitara

| Paerewa | Whakaahuatanga |

| ASTM A179/A179M | Whakawhiti wera me nga ngongo condenser me te matao kore utu. |

| API 5L | Raina paipa. |

| ASTM A53M | He Paihere Paiherea me te Paipa Maamaa Korekau me te Paariki. |

| ASTM A106M | putorino waro maitai mo te ratonga pāmahana teitei. |

| ASTM A105M | Waro maitai forgings mō tono paipa. |

| ASTM A234M | Ko nga taputapu paipa o te waro waro mahi me te rino koranu mo te mahi mahana me te teitei. |

| ASTM 3799 | Ko nga taputapu paipa rino, he wiri me te turanga turanga mo te umanga hinu. |

| AS 1163 | Ko nga wahanga hoohanga maitai |

| AS 1074 | Ngongo maitai me nga ngongo mo te mahi noa |

| BS13872 | Ko nga ngongo maitai me nga ngongo me nga ngongo |

| Paerewa | Momo paipa | Karaehe | Kōeke |

| API SPEC 5L ISO 3183 | SMLS | PLS1 | L245B, L290 X42, L320 X46 , L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| PLS2 | L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q , L485Q X70Q

| ||

| PLS2 Taiao kawa | L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS

| ||

| WELD | PLS1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| PLS2 | L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, | ||

| Paerewa | Kōeke |

| ASTM A 53 M | A , B |

| ASTM A 106M | A, B, C |

| JIS G 3454 | STPG 370, STPG 410 |

| JIS G 3455 | STPG370, STPG410, STPG480 |

| JIS G 3456 | STPG370, STPG410, STPG480 |

Kōeke: Hanganga matū (%):

| Paerewa | Kōeke | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| ASTMA 53M | A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | - | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| ASTM A 106M | A | ≤0.25 | ≥0.10 | 0.27-0.93 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| JIS G 3454 | STPG 370 | ≤0.25 | ≤0.35 | 0.30-0.90 | ≤0.040 | ≤0.040 | - | - | - | - | - |

| STPG 410 | ≤0.30 | ≤0.35 | 0.30-1.00 | ≤0.040 | ≤0.040 | - | - | - | - | - | |

| JIS G 3455 | STS 370 | ≤0.25 | 0.10-0.35 | 0.30-1.10 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STS 410 | ≤0.30 | 0.10-0.35 | 0.30-1.40 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STS 480 | ≤0.33 | 0.10-0.35 | 0.30-1.50 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| JIS G 3456 | STPT 370 | ≤0.25 | 0.10-0.35 | 0.30-0.90 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STPT 410 | ≤0.30 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STPT 480 | ≤0.33 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - |

Te maimoatanga mata o te putorino maitai: Hei whakapai ake i te oranga ratonga o te pipeline hinu, ka whakahaerehia te maimoatanga mata ki te whakahaere i te whakakotahitanga o te putorino maitai me te paninga anticorrosive. Ko nga tikanga tukatuka noa ko: te horoi, te whakakore i nga taputapu, te kohi, te pupuhi pupuhi. e wha nga waahanga.1 te horoi Ko te hinu, te puehu, te whakahinuhinu, te mea pararopi e piri ana ki te mata o te putorino rino, te nuinga o te whakamahi i te whakarewa, te whakaehunga hei horoi i te mata.Heoi, ko te waikura, te kiri waikura, me te para whakahiato i runga i te mata o te putorino maitai e kore e taea te tango, na etahi atu e hiahiatia ana nga tikanga maimoatanga.Tool rust removalSteel pipe mata waikura, waikura, fehokotaki'anga para, ka taea te whakamahi i te paraihe waea maitai ki te horoi me te whakakoi i te mata treatment.Tool derusting ka taea te wehea ki a-ringa me te mana, ka taea e te derusting taputapu ā-ringa tae Sa 2 taumata, mana Ka taea e te whakakore i te taputapu te tae ki te taumata Sa3. Mena ka piri te mata o te paipa rino ki te kiri waikura tino kaha, ka kore pea e taea te tango i te waikura me te awhina o nga taputapu, na me rapu etahi atu huarahi.3 pickling Ko nga tikanga pikinga noa ko te matū me te electrolysis.Engari ko te tiki matū anake e whakamahia ana mo te tiaki i te waikura paipa.Ka taea e te pikau matū te whakatutuki i tetahi tohu o te ma me te taratara i runga i te mata o te paipa maitai, he pai mo nga raina punga o muri. pupuhi (kirikiri) i muri i te tukatuka ano.4 pupuhi pupuhi mo te tango waikuraNa te motuka mana nui te taraiwa tere tere tere, te kirikiri rino, te pupuhi rino, te waahanga, nga kohuke me etahi atu waea abrasive i raro i te mahi o te kaha centrifugal i runga i te rehu paipa rino me te pupuhi papatipu, tino tango i te waikura, waikura. me te paru i runga i tetahi ringa, i runga i te tahi atu te ringa, paipa maitai i raro i te mahi o te abrasive pānga tutu me te kaha waku, ki te whakatutuki i te roughness kākahu e hiahiatia ana.I roto i nga tikanga maimoatanga e wha, pupuhi ngingio me derusting ko te tikanga maimoatanga pai mo te putorino derusting.Ko te tikanga, ko te pupuhi pupuhi me te whakakore i te nuinga o te waa e whakamahia ana mo te maimoatanga mata o roto o te putorino maitai, a ko te pupuhi pupuhi me te pupuhi ka whakamahia mo te maimoatanga mata o waho o te putorino maitai.

Rehu peita

Rehu peita

Takai parewai