Borî/Tîtanyûm

Tîtanyûmê lûleya bêqelp bi perçebûna lingê titaniumê ve tê hilanîn, bi lûleya tîtaniumê tê derxistin.Dûv re lûleyên titanium bi mezinahiya guncan bi rêze pêvajoyên wekî teknolojiya pirzimanî, rijandin, hilgirtin, û qirkirinê hilberînin.

Tîtanyûmê ziravkirî bi hilbijartina qalindiyek maqûl ya plakaya titanyumê ya sar a bi kalîteya bilind, piştî pêvajoya xêzkirin, birrîn û şuştinê, dûv re plakaya titaniumê di nav tubular de hildiweşîne, ji hêla tevahiya alavên weldingê ve tê welding.Amûrên welding ên me yên pêşkeftî qalîteya welding garantî kirin.Di dawiyê de ji bo hilberandina lûleya titaniumê ya hêja dibe alîkar.

Tîtanyûmê lûleyek bêserûber

Not: Gr1, Gr2, Gr7, Gr9, Gr11, Gr12, Gr16 hwd.

Dirêjahiya derve: 3 ~ 110 mm

Stûrahiya dîwar: 0.1~5.5mm

Dirêjahî: ≤19000mm

Tîtanium lûleya weldê

Not: Gr1, Gr2, Gr7, Gr9, Gr11, Gr12, Gr16 hwd.

Dirêjahiya derve: 10 ~ 1000 mm

Qalindahiya dîwar: 0,5 ~ 5,5 mm

Dirêjahî: ≤19000mm

Gr5, Gr23 titanium alloy boriyeke bêqel

Dirêjahiya derve: 20 ~ 110 mm

Stûrahiya dîwar: 1~50mm

Dirêjahî: ≤3000mm

Pêvajoya çêkirinê: Drilling, Hot Rolling

| BORÎYA TÎTANIYÛMÊ SEMLE | ||||||||||

|

| S10 | S40 | S80 | |||||||

| Pipe Size | OD | Dîwar | Inside Dia. | lbs / ft | Dîwar | Inside Dia. | lbs / ft | Dîwar | Inside Dia. | lbs / ft |

| 1/8 | .405 | .049 | .307 | .1072 | .068 | .269 | .1408 | .095 | .215 | .1810 |

| 1/4 | .540 | .065 | .410 | .1897 | .088 | .364 | .2442 | .119 | .302 | .3079 |

| 3/8 | .675 | .065 | .545 | .2437 | .091 | .493 | .3266 | .126 | .423 | .4251 |

| 1/2 | .840 | .083 | .674 | .3861 | .109 | .622 | .4896 | .147 | .546 | .6260 |

| 3/4 | 1.050 | .083 | .884 | .4932 | .113 | .824 | .6506 | .154 | .742 | .8479 |

| 1 | 1.315 | .109 | 1.097 | .8078 | .133 | 1.049 | .9660 | .179 | .957 | 1.2495 |

| 1-1/4 | 1.660 | .109 | 1.442 | 1.0389 | .140 | 1.380 | 1.3077 | .191 | 1.278 | 1.7242 |

| 1-1/2 | 1.900 | .109 | 1.681 | 1.1996 | .145 | 1.610 | 1.5637 | .200 | 1.500 | 2.0893 |

| 2 | 2.375 | .109 | 2.157 | 1.5178 | .154 | 2.067 | 2.1018 | .218 | 1.939 | 2.8895 |

| 2-1/2 | 2.875 | .120 | 2.635 | 2.0315 | .203 | 2.469 | 3.3331 | .276 | 2.323 | 4.4080 |

| 3 | 3.500 | .120 | 3.260 | 2.4924 | .216 | 3.068 | 4.3589 | .300 | 2.900 | 5.8992 |

| 3-1/2 | 4.000 | .120 | 3.760 | 2.8611 | .226 | 3.548 | 5.2412 | .318 | 3.364 | 7.1950 |

| 4 | 4.500 | .120 | 4.260 | 3.2298 | .237 | 4.026 | 6.2085 | .337 | 3.826 | 8.6210 |

| 5 | 5.563 | .134 | 5.295 | 4.4704 | .258 | 5.047 | 8.4106 | .375 | 4.813 | 11.9550 |

| 6 | 6.625 | .134 | 6.357 | 5.3449 | .280 | 6.065 | 10.917 | .432 | 5.761 | 16.440 |

| BOLIYA TÎTANIUMÊ WELDED | |||||||

|

| S10 | S40 | |||||

| Pipe Size | OD | Dîwar | Inside Dia. | lbs / ft | Dîwar | Inside Dia. | lbs / ft |

| 3/4 | .1.050 | .083 | .884 | .4932 | .113 | .824 | .6506 |

| 1 | 1.315 | .109 | 1.097 | .8078 | .133 | 1.049 | .9660 |

| 1-1/4 | 1.660 | .109 | 1.442 | 1.0389 | .140 | 1.380 | 1.3077 |

| 1-1/2 | 1.900 | .109 | 1.681 | 1.1996 | .145 | 1.610 | 1.5637 |

| 2 | 2.375 | .109 | 2.157 | 1.5178 | .154 | 2.067 | 2.1018 |

| 2-1/2 | 2.875 | .120 | 2.635 | 2.0315 | .203 | 2.469 | 3.3331 |

| 3 | 3.500 | .120 | 3.260 | 2.4924 | .216 | 3.068 | 4.3589 |

| 3-1/2 | 4.000 | .120 | 3.760 | 2.8611 | .226 | 3.548 | 5.2412 |

| 4 | 4.500 | .120 | 4.260 | 3.2298 | .237 | 4.026 | 6.2085 |

| 5 | 5.563 | .134 | 5.295 | 4.4704 | .258 | 5.047 | 8.4106 |

| 6 | 6.625 | .134 | 6.357 | 5.3449 | .280 | 6.065 | 10.917 |

| 8 | 8.625 | .148 | 8.329 | 7.7095 | .322 | 7.981 | 16.429 |

| 10 | 10.750 | .165 | 10.420 | 10.732 | .365 | 10.020 | 23.293 |

| 12 | 12.750 | .180 | 12.390 | 13.904 | .375 | 12.000 | 28.517 |

| 14 | 14.000 | .188 | 13.624 | 15.956 | .375 | 13.250 | 31.397 |

| 16 | 16.000 | .188 | 15.624 | 18.267 | .375 | 15.250 | 36.006 |

| 18 | 18.000 | .188 | 17.624 | 20.577 | .375 | 17.250 | 40.615 |

| 20 | 20.000 | .218 | 19.564 | 26.500 | .375 | 19.250 | 45.223 |

| 24 | 24.000 | .250 | 23.500 | 36.486 | .375 | 23.250 | 54.441 |

ASTM B338 - 10e1 Specification Standard ji bo Tîtanyûm û Tîtanyûmê Tîtanyûmê Tîtanyûm û Tîtanyûmên Tîtanyûmê yên Bêqel û Weldkirî yên Ji bo Kondensator û Veguhezerên Germê

ASTM B862 - 09 Specification Standard ji bo Titanium û Titanium Alloy Bope Welded

ASTM B861 - 10 Specification Standard ji bo Tîtanyum û Tîtanyûmê Aloy Tîtanyûm, ASTM B337

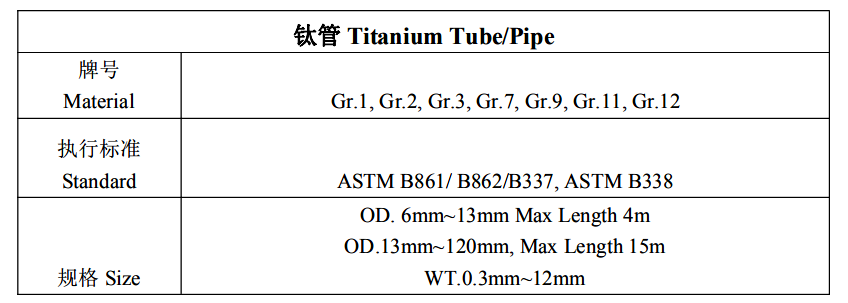

| Tîtanyûm lûle / lûle | Navê hilberê | Sinif | Specification (mm) | Rêzan |

| Tube Seamless | Gr.1 Gr.2 Gr.7 Gr.9 Gr.12

| OD(3-114)×THK(0.5-10) ×≤ dirêjî 12000 | ASTM B337 ASTM B338 ASTM B 861 | |

| Welding Pipe | Gr.1 Gr.2 Gr.7 Gr.12 | ≥OD133 | ASTM B862 | |

| Tube (Rûsya) | BT1-0 | OD(3-114)×THK(0.5-10) ×≤ dirêjî 12000 | GOST22879 | |

Pêkhatina kîmyewî

| Sinif | Pêkhatina kîmyewî, sedî giran (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Hêmanên din Max.herkes | Hêmanên din Max.hemî | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5,5 ~ 6,75 | 3.5-4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0,12~0,25 | - | 0,12~0,25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5-3.5 | 2.0-3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0,12~0,25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6-0.9 | 0.2-0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04-0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5-6.5 | 3.5-4.5 | - | - | - | - | 0.1 | 0.1 |

Taybetmendiyên fizîkî

| Sinif | Taybetmendiyên fizîkî | ||||

| Hêza tîrêjê Min | Hêza hilberînê Kêm (0,2%, nefîkirin) | Dirêjbûn di 2 in an 50 mm de Min (%) | |||

| ksi | MPa | ksi | MPa | ||

| Gr1 | 35 | 240 | 20 | 138 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 20 |

| Gr5 | 130 | 895 | 120 | 828 | 10 |

| Gr7 | 50 | 345 | 40 | 275 | 20 |

| Gr9 | 90 | 620 | 70 | 483 | 15 |

| Gr11 | 35 | 240 | 20 | 138 | 24 |

| Gr12 | 70 | 483 | 50 | 345 | 18 |

| Gr16 | 50 | 345 | 40 | 275 | 20 |

| Gr23 | 120 | 828 | 110 | 759 | 10 |