Titanium nplhaib

Loj titanium rings yog tsim los ntawm lub loj sib tsoo lub nplhaib tshuab, me me titanium rings yuav ua tau tiav los ntawm forging tshuab.Raws li lub tuam txhab nrog ntau tshaj 20 xyoo ntawm kev tsim khoom, peb muaj cov txheej txheem nruj forging thiab kev khiav hauj lwm phau ntawv, nrog rau cov kauj ruam cua sov, lub sij hawm cua sov thiab lub sij hawm txuag hluav taws xob.Lub 35MN thiab 16MN ceev forging tshuab tau lees paub ntau yam forging nyob rau hauv qhov haum qhov kub thiab txias, thiab hloov lub cev sab hauv ntawm titanium rings.Zoo heev txhim kho qhov zoo ntawm peb cov khoom.

Ntxiv nrog rau titanium nplhaib, peb kuj muab kev tsim cov titanium disc, titanium thaiv thiab lwm yam.

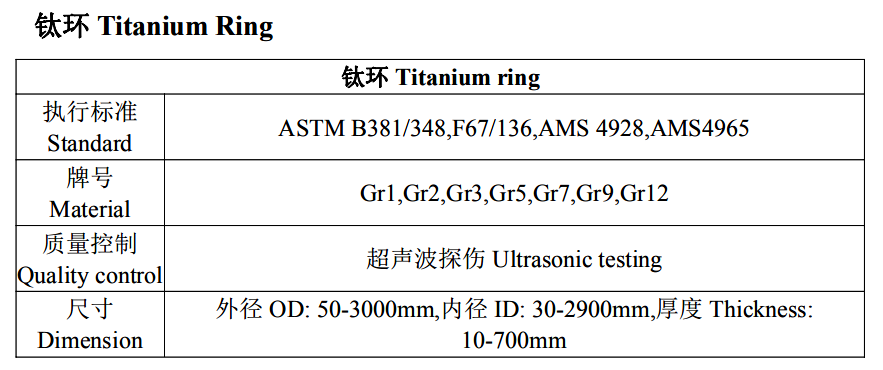

| npe khoom | Titanium nplhaib |

| Loj | OD (max 3000mm)×ID (max2900mm)×ntev (qhov ntev tshaj plaws 1000mm) |

| Qib | TA1/TA2/TA5/TA6/TA9/TA10/TA15/TA19/TX1/TC2/TC4/TC11/ GR1/GR2/GR5/GR7/GR9/GR12/GR23 |

| Cov qauv | ASTM B381/348, F67/136, AMS4928, AMS4965,AMS,MIL,DIN,BS,JIS,GB / T,ISOlwm |

| Qhov ntom | 4.51g / cm3 Kev ua haujlwm siab muaj forging, gr12 Titanium forged dov nplhaib |

| Technology | Forging, dov, sib tsoo kev ua haujlwm siab muaj forging GR12 titanium forging dov nplhaib |

| Hom | Cov txheej txheem ntawm seamless nplhaib dov yuav txiav ib lub qhov nyob rau hauv cov khoom forged thiab dov mus rau hauv ib lub nplhaib nyias. Piv rau phaj firing lossis taub qab vuam, lub nplhaib forged dov muab kev txhim kho zoo nrog lub nplhaib du Ntiv nplhaib kev ua haujlwm siab kev lag luam forged GR12 titanium forged dov nplhaib |

| Daim ntawv thov | 1. Electroplating; 2.Tshuaj thiab petrochemical technology; 3.Kev kho mob siab kev lag luam forging GR12 titanium forging dov nplhaib |

ASTM B381/348, F67/136, AMS4928, AMS4965

Tshuaj muaj pes tsawg leeg

| Qib | Tshuaj muaj pes tsawg leeg, qhov hnyav feem pua (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Lwm Yam Khoom Max.txhua | Lwm Yam Khoom Max.tag nrho | |

| Gr1 | 0.08 ib | 0.18 | 0.03 ib | 0.015 ib | 0.20 ib | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr 2 | 0.08 ib | 0.25 | 0.03 ib | 0.015 ib | 0.30 Nws | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 ib | 0.25 | 0.03 ib | 0.015 ib | 0.30 Nws | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr 5 | 0.08 ib | 0.20 ib | 0.05 Nws | 0.015 ib | 0.40 Nws | 5.5-6.75 Nws | 3.5 ~ 4.5 hli | — | — | — | — | 0.1 | 0.4 |

| gr 7 | 0.08 ib | 0.25 | 0.03 ib | 0.015 ib | 0.30 Nws | — | — | 0.12-0.25 Nws | — | 0.12-0.25 Nws | — | 0.1 | 0.4 |

| gr9 ua | 0.08 ib | 0.15 | 0.03 ib | 0.015 ib | 0.25 | 2.5 ~ 3.5 hli | 2.0 ~ 3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr 11 | 0.08 ib | 0.18 | 0.03 ib | 0.15 | 0.2 | — | — | 0.12-0.25 Nws | — | — | — | 0.1 | 0.4 |

| Gr 12 | 0.08 ib | 0.25 | 0.03 ib | 0.15 | 0.3 | — | — | — | — | 0.6-0.9 hli | 0.2 ~ 0.4 hli | 0.1 | 0.4 |

| Gr 16 | 0.08 ib | 0.25 | 0.03 ib | 0.15 | 0.3 | — | — | 0.04-0.08 Nws | — | — | — | 0.1 | 0.4 |

| Gr 23 | 0.08 ib | 0.13 | 0.03 ib | 0.125 Nws | 0.25 | 5.5-6.5 hli | 3.5 ~ 4.5 hli | — | — | — | — | 0.1 | 0.1 |

Lub cev muaj zog

| Qib | Lub cev muaj zog | |||||

| Tensile zog Min | Yield zog Tsawg (0.2%, offset) | Elongation hauv 4D Min (%) | Kev txo qis ntawm cheeb tsam Min (%) | |||

| ksi ua | MPa | ksi ua | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr 2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 ib | 15 | 25 |

| Gr 5 | 130 | 895 ib | 120 | 828 ib | 10 | 25 |

| gr 7 | 50 | 345 | 40 | 275 | 20 | 30 |

| gr9 ua | 90 | 620 | 70 | 483 ib | 15 | 25 |

| Gr 11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr 12 | 70 | 483 ib | 50 | 345 | 18 | 25 |

| Gr 16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr 23 | 120 | 828 ib | 110 | 759 ib | 10 | 15 |